| Citation: | Tian-ming Gao, Na Fan, Wu Chen, Tao Dai, 2023. Lithium extraction from hard rock lithium ores (spodumene, lepidolite, zinnwaldite, petalite): Technology, resources, environment and cost, China Geology, 6, 137-153. doi: 10.31035/cg2022088 |

Lithium extraction from hard rock lithium ores (spodumene, lepidolite, zinnwaldite, petalite): Technology, resources, environment and cost

-

Abstract

Lithium production in China mainly depends on hard rock lithium ores, which has a defect in resources, environment, and economy compared with extracting lithium from brine. This paper focuses on the research progress of extracting lithium from spodumene, lepidolite, petalite, and zinnwaldite by acid, alkali, salt roasting, and chlorination methods, and analyzes the resource intensity, environmental impact, and production cost of industrial lithium extraction from spodumene and lepidolite. It is found that the sulfuric acid method has a high lithium recovery rate, but with a complicated process and high energy consumption; alkali and chlorination methods can directly react with lithium ores, reducing energy consumption, but need to optimize reaction conditions and safety of equipment and operation; the salt roasting method has large material flux and high energy consumption, so require adjustment of sulfate ratio to increase the lithium yield and reduce production cost. Compared with extracting lithium from brine, extracting lithium from ores, calcination, roasting, purity, and other processes consume more resources and energy; and its environmental impact mainly comes from the pollutants discharged by fossil energy, 9.3‒60.4 times that of lithium extracted from brine. The processing cost of lithium extraction from lepidolite by sulfate roasting method is higher than that from spodumene by sulfuric acid due to the consumption of high-value sulfate. However, the production costs of both are mainly affected by the price of lithium ores, which is less competitive than that of extracting lithium from brine. Thus, the process of extracting lithium from ores should develop appropriate technology, shorten the process flow, save resources and energy, and increase the recovery rate of related elements to reduce environmental impact and improve the added value of by-products and the economy of the process.

-

-

References

Albertani BM. 2018. The leaching of α-spodumene. Perth, Western Austraila, Murdoch University, Ph. D thesis, 1‒114. Alessia A, Alessandro B, Maria VG, Carlos VA, Francesca B. 2021. Challenges for sustainable lithium supply: A critical review. Journal of Cleaner Production, 300, 126954. doi: 10.1016/j.jclepro.2021.126954. Ambrose H, Kendall A. 2019. Understanding the future of lithium: Part 1, resource model. Journal of Industrial Ecology, 24(1), 80–89. doi: 10.1111/jiec.12949. Anovitz LM, Blencoe JG, Palmer DA. 2006. Method of extracting lithium. US: US2006/0171869 A1. 2008-11-26. Barbosa LI, González JA, CarmenRuiz MD. 2015. Extraction of lithium from β-spodumene using chlorination roasting with calcium chloride. Thermochimica Acta, 605, 63–67. doi: 10.1016/j.tca.2015.02.009. Barbosa LI, Valente G, Orosco RP, González JA. 2014. Lithium extraction from β-spodumene through chlorination with chlorine gas. Minerals Engineering, 56, 29–34. doi: 10.1016/j.mineng.2013.10.026. Barbosa LI, Valente NG, González JA. 2013. Kinetic study on the chlorination of β-spodumene for lithium extraction with Cl2 gas. Thermochimica Acta, 557, 61–67. doi: 10.1016/j.tca.2013.01.033. Bishimbayeva G, Zhumabayeva D, Zhandayev N, Nalibayeva A, Shestakov K, Levanevsky I, Zhanabayeva A. 2018. Technological improvement lithium recovery methods from primary resources. Oriental Journal of Chemistry, 34(6), 2762–2769. doi: 10.13005/ojc/340611. Chen Y, Liao T, Chen BZ, Tian QQ. 2011b. Extraction of lithium from spodumene by sodium carbonate autoclave process. Nonferrous Metals (Extractive Metallurgy), (9), 21–32 (in Chinese with English abstract). doi: 10.3969/j.issn.1007-7545.2011.09.006. Chen Y, Tian QQ, Chen BZ, Shi XC, Liao T. 2011a. Preparation of lithium carbonate from spodumene by a sodium carbonate autoclave process. Hydrometallurgy, 109(1‒2), 43‒46. doi: 10.1016/j.hydromet.2011.05.006. Cheng Y, Li YS, Chen CH. 2012. Study on preparation of lithium carbonate from lepidolite concentrate. Inorganic Salt Industry, 44(4), 16–19 (in Chinese with English abstract). doi: 10.3969/j.issn.1006-4990.2012.04.006. Chubb PA. 1963. Treatment of lithium ores. US: US3073673A. 1963-01-15. CMCA. 2020. China ENFI has achieved remarkable results in extracting battery grade lithium carbonate by soda ash pressure boiling method. https://www.zgyj.org.cn/directors/291500201448.html (Accessed 01-18−2020) . Ebensperger A, Maxwell P, Moscoso C. 2005. The lithium industry: Its recent evolution and future prospects. Resources Policy, 30(3), 218–231. doi: 10.1016/j.resourpol.2005.09.001. Ellestad RB, Milne LK. 1950. Method of extracting lithium values from spodumene ores. USA: US4964748A. 1950-07-25. Feng WP, Xie JL, Tang JL, Ning WY, Zheng XF. 2016. Study on the extraction of lithium from lepidolite. Fine Chemical Intermediates, 46(3), 66–69 (in Chinese with English abstract). doi: 10.19342/j.cnki.issn.1009-9212.2016.03.017. Feng YL, Fu XR, Liu Y. 2018. Study on preparation of lithium carbonate from lithium mica. Light Metal, (4), 19–19,23 (in Chinese with English abstract). doi: 10.13662/j.cnki.qjs.2018.04.005. Gabra GG, Torma AE, Olivier CA. 1975. Pressure leaching of beta-spodumene by sodium chloride. Canadian Metallurgical Quarterly, 14(4), 355–359. doi: 10.1179/000844375795050049. GB/T51382. 2019. Standard for process design of lithium refinery. China Minstry of Housing and Urban-Rural Development, China State Administration for Market Regulation (in Chinese). Gmar S, Chagnes A. 2019. Recent advances on electrodialysis for the recovery of lithium from primary and secondary resources. Hydrometallurgy, 189, 105124. doi: 10.1016/j.hydromet.2019.105124. Gu GZ, Gao TM. 2021. Sustainable production of lithium salts extraction from ores in China: Cleaner production assessment. Resources Policy, 74, 102261. doi: 10.1016/j.resourpol.2021.102261. Guo CP, Zhou J, Wen XQ, Pu J, Wang YX, Yuan DL. 2014. Extraction of lithium from lepidolite by sulfate process. Inorganic Chemicals Industry, 46(3), 41–44 (in Chinese with English abstract). doi: 10.3969/j.issn.1006-4990.2014.03.011. Guo H, Kuang G, Li H, Pei WT, Wang HD. 2021. Enhanced lithium leaching from lepidolite in continuous tubular reactor using H2SO4+H2SiF6 as lixiviant. Transactions of Nonferrous Metals Society of China, 31(7), 2165–2173. doi: 10.1016/S1003-6326(21)65646-7. Guo H, Kuang G, Wan H, Yang Y, Yu HZ, Wang HD. 2019. Enhanced acid treatment to extract lithium from lepidolite with a fluorine-based chemical method. Hydrometallurgy, 183, 9–19. doi: 10.1016/j.hydromet.2018.10.020. Guo H, Kuang G, Wang HD, Yu HZ, Zhao XK. 2017. Investigation of enhanced leaching of lithium from α-spodumene using hydrofluoric and sulfuric acid. Minerals, 7(11), 205. doi: 10.3390/min7110205. Hu P, Liu M, Fu LH. 2016. Lithium carbonate process technical analysis. World Nonferrous Metals, (20), 48–49 (in Chinese with English abstract). Hu Z. 2019. Analysis of typical lithium extraction from mines and its economic benefit. Journal of Salt Science and Chemical Industry, 48(3), 5–8 (in Chinese with English abstract). doi: 10.16570/j.cnki.issn1673-6850.2019.03.003. Hunwick R. 2017. Recovery of lithium from silicate minerals. USA: US2017/017522A1. 2017-01-19. Jandová J, Dvořák P, Vu HN. 2010. Processing of zinnwaldite waste to obtain Li2CO3. Hydrometallurgy, 103(1‒4), 12‒18. doi: 10.1016/j.hydromet.2010.02.010. Jandová J, Vu H, Belková T, Peter D, Kondás J. 2009. Obtaining Li2CO3 from zinnwaldite wastes. Ceramics Silikaty, 52(2), 108–112. doi: 10.1016/j.ceramint.2008.07.001. Jiang SY, Zhang L, Li FY, Hua H, Liu X, Yuan ZW, Wu HJ. 2020. Environmental impacts of lithium production showing the importance of primary data of upstream process in life-cycle assessment. Journal of Environmental Management, 262, 110253. doi: 10.1016/j.jenvman.2020.110253. Karrech A, Azadi MR, Elchalakani M, Shahin MA, Seibi AC. 2020. A review on methods for liberating lithium from pegmatities. Minerals Engineering, 145, 106085. doi: 10.1016/j.mineng.2019.106085. Kondás J, Jandová J. 2006. Lithium extraction from zinnwaldite wastes after gravity dressing of Sn-W ores. Acta Metallurgica Slovaca, 12, 197–202. Kuai YQ, Yao WG, Ma HW, Liu MT, Gao Y, Guo RY. 2021. Recovery lithium and potassium from lepidolite via potash calcination-leaching process. Minerals Engineering, 160, 106643. doi: 10.1016/j.mineng.2020.106643. Kuang G, Chen ZB, Guo H, Li MH. 2012. Lithium extraction mechanism from α-spodumene by fluorine chemical method. Advanced Materials Research, 524‒527, 2011‒2016. doi: 10.4028/www.scientific.net/AMR.524-527.2011. Kuang G, Lin C, Wang ZQ, Ye CS, Lin RY. 2010. Fluorine chemical extraction of lithium from lepidolite. China: CN101885496A, 2010–11-17. Kuang G, Liu Y, Li H, Xing SZ, Li FJ, Guo H. 2018. Extraction of lithium from β-spodumene using sodium sulfate solution. Hydrometallurgy, 177, 49–56. doi: 10.1016/j.hydromet.2018.02.015. Kuang G, Sun JX, Yang JX, Jin R, Hu S, Li H, Shan YW, Chen GH. 2014. A method for the production of lithium hydroxide from spodumene using pipe reacto. China: CN 104003428 A, 2014–08-27. Lee S. 2018. Extraction of Lithium from Spodumene by Alkali Fusion. Seoul, Seoul National University, Master thesis, 1‒72. Li G, Yang J, Yang J. 2017. Literature review of extracting lithium from lepidolite. Bulletin of the Chinese Ceramic Society, 35(5), 1599–1604 (in Chinese with English abstract). doi: 10.16552/j.cnki.issn1001-1625.2017.05.024. Li H, Eksteen J, Kuang G. 2019. Recovery of lithium from mineral resources: State-of-the-art and perspectives – A review. Hydrometallurgy, 189, 105129. doi: 10.1016/j.hydromet.2019.105129. Li LJ, Peng XW, Shi D, Zhang LC, Li HF, Song FG, Nie F, Ji LM, Song XX, Zeng ZM. 2018. Eco-friendly separation and effective applications of lithium resources from various brine with lithium: Their extractant and extraction system. Journal of Salt Lake Research, 26(4), 1–10 (in Chinese with English abstract). doi: 10.12119/j.yhyj.201804001. Lileev I, Sachenko-Sakum L, Guseva I. 1968. Reaction of hydrated lithium dialuminate with sodium hydroxide solutions. Russian Journal of Inorganic Chemistry, 13, 213–219. Liu H, Azimi G. 2021. Process analysis and study of factors affecting the lithium carbonate crystallization from sulfate media during lithium extraction. Hydrometallurgy, 199, 105532. doi: 10.1016/j.hydromet.2020.105532. Liu L, Liu L, Zhang L, Wang W, Liu HZ, Cao YH. 2021. Research on recovery of lithium from lepidolite concentrate by chlorination roasting and water leaching. Nonferrous Metals (Extractive Metallurgy), (2), 72–76 (in Chinese with English abstract). doi: 10.3969/j.issn.1007-7545.2021.02.011. Liu LJ, Wang DH, Liu XF, Li JK, Dai HZ, Yan WD. 2017. The main types, distribution features and present situation of exploration and development for domestic and foreign lithium mine. Geology in China, 44(2), 263–278 (in Chinese with English abstract). doi: 10.12029/gc20170204. Liu XK, Qi L, Jian XD, Kuang G. 2014. A new technology for lithium extraction from lepidolite. China Nonferrous Metals, (12), 66–67. Liu YL, Chen WY, Liu GS. 2013. Distribution of lithium mineral resources in China and extraction techniques of lithium carbonate. Inorganic Chemicals Industry, 45(6), 8–10 (in Chinese with English abstract). doi: 10.3969/j.issn.1006-4990.2013.06.003. Luong VT, Kang DJ, An JW, Dao DA, Kim MJ, Tran T. 2014. Iron sulphate roasting for extraction of lithium from lepidolite. Hydrometallurgy, 141, 8–16. doi: 10.1016/j.hydromet.2013.09.016. Margarido F, Vieceli N, Durão F, Guimarães C, Nogueira C. 2014. Minero-metallurgical processes for lithium recovery from pegmatitic ores. Comunicaç õ es Geológicas, 101, 795–798. Martin G, Pätzold C, Bertau M. 2017a. Integrated process for lithium recovery from zinnwaldite. International Journal of Mineral Processing, 160, 8–15. doi: 10.1016/j.minpro.2017.01.005. Martin G, Schneider A, Voigt W, Bertau M. 2017b. Lithium extraction from the mineral zinnwaldite: Part II: Lithium carbonate recovery by direct carbonation of sintered zinnwaldite concentrate. Minerals Engineering, 110, 75–81. doi: 10.1016/j.mineng.2017.04.009. Meng GS. 2008. Co-existence of extracting lithium from ores and salt lake brines. World Nonferrous Metals, (2), 67–69. Meshram P, Pandey BD, Mankhand TR. 2014. Extraction of lithium from primary and secondary sources by pre-treatment, leaching and separation: A comprehensive review. Hydrometallurgy, 150, 192–208. doi: 10.1016/j.hydromet.2014.10.012. Mohr SH, Mudd GM, Giurco D. 2012. Lithium resources and production: Critical assessment and global projections. Minerals, 2(1), 65–84. doi: 10.3390/min2010065. Morozova LN. 2018. Lithium Kolmozero deposit of rare metal pegmatites: New data on rare element composition (Kola Peninsula). Lithosphere (Russia), 18(1), 82–98. doi: 10.24930/1681-9004-2018-18-1-082-098. Pan T, Li SP, Wang T, Han G, Jia JT. 2022. Metallogenic characteristic and prospecting potential of lithium deposits in Qinghai province. Acta Geological Sinica, 96. doi: 10.19762/j.cnki.dizhixuebao.2022023. Peng AP, Song QR. 2016. Technology status and development trend of lithium deep processing industry. World Nonferrous Metals, (14), 15–22 (in Chinese with English abstract). Peng JZ. 2019. Analysis of the domestic production technology and economic benefit of lithium carbonate. Journal of Salt Science and Chemical Industry, 48(10), 18‒20 (in Chinese with English abstract). doi: 10.16570/j.cnki.issn1673-6850.2019.10.005. Peterson JA, Gloss GH. 1959. Lithium values recovery process. USA: US2893828. 1959-07-07. Qin YN. 2004. The rawmateial of lithium molybdate – The technology and improment for producing lithium carbonate. China Molybdenum Industry, 28(6), 26–28 (in Chinese with English abstract). doi: 10.3969/j.issn.1006-2602.2004.06.007. Rajesh HM, Knoper MW, Belyanin GA, Safonov OG, Schmidt C. 2020. Petalite postdating spodumene in pegmatite as a consequence of the ~2.02 Ga meteorite impact in the Vredefort structure, southern Africa. Lithos, 376‒377, 105760. doi: 10.1016/j.lithos.2020.105760. Ran JW, Liu X, Pei J, Yin WX. 2016. Development of production technology of lithium resource in China. Guangzhou Chemical Industry, 44(13), 4–6 (in Chinese with English abstract). doi: 10.3969/j.issn.1001-9677.2016.13.002. Rosales GD, Ruiz MC, Rodriguez MH. 2014. Novel process for the extraction of lithium from β-spodumene by leaching with HF. Hydrometallurgy, 147‒148, 1‒6. doi: 10.1016/j.hydromet.2014.04.009. Rosales GD, Ruiz MC, Rodriguez MH. 2016. Study of the extraction kinetics of lithium by leaching β-spodumene with hydrofluoric acid. Minerals, 6(4), 98. doi: 10.3390/min6040098. Samoilov VI, Kulenova NA, Sheregeda ZV, Gadylbekova LG, Agapov VA, Shushkevich LV. 2008. Integrated processing of spodumene in hydrometallurgy. Russian Journal of Applied Chemistry, 81(3), 494–496. doi: 10.1134/s1070427208030312. Samoilov VI, Onalbaeva ZS, Adylkanova MA, Kokaeva GA, Abdulina SA. 2018. Development of alkaline decomposition of lepidolite concentrate by melting with calcined soda and melt comprehensive sulfuric acid treatment. Metallurgist, 62(3‒4), 361‒368. doi: 10.1007/s11015-018-0669-z. Schneider A, Schmidt H, Meven M, Brendler E, Kirchner J, Martin G, Bertau M, Voigt W. 2017. Lithium extraction from the mineral zinnwaldite: Part I: Effect of thermal treatment on properties and structure of zinnwaldite. Minerals Engineering, 111, 55–67. doi: 10.1016/j.mineng.2017.05.006. Setoudeh N, Nosrati A, Welham NJ. 2020. Lithium extraction from mechanically activated of petalite-Na2SO4 mixtures after isothermal heating. Minerals Engineering, 151, 106294. doi: 10.1016/j.mineng.2020.106294. Shang X, Meng YH, Zhang Q, Yang HM. 2020. Lithium extraction and strategic application of lithium-rich minerals. Conservation and Utilization of Mineral Resources, 39(6), 152–158 (in Chinese with English abstract). doi: 10.13779/j.cnki.issn1001-0076.2019.06.020. Shi Y. 1982. Comprehensive smelting process of lithium mica by limestone method. Rare Metal, (3), 11–13. doi: 10.13373/j.cnki.cjrm.1982.03.002. Siame E, Pascoe RD. 2011. Extraction of lithium from micaceous waste from china clay production. Minerals Engineering, 24(14), 1595–1602. doi: 10.1016/j.mineng.2011.08.013. Sitando O, Crouse PL. 2012. Processing of a Zimbabwean petalite to obtain lithium carbonate. International Journal of Mineral Processing, 102‒103, 45‒50. doi: 10.1016/j.minpro.2011.09.014. Sterba J, Krzemień A, Valverde GF, Álvarez ID, Fernández CC. 2020. Energy-sustainable industrialized growth in the Czech Republic: The Cínovec lithium mining project. Resources Policy, 68, 101707. doi: 10.1016/j.resourpol.2020.101707. Su H, Zhu ZW, Wang LN, Qi T. 2019. Research progress in extraction and recovery of lithium from hard-rock ores. CIESC Journal, 70(1), 10–23 (in Chinese with English abstract). doi: 10.11949/j.issn.0438-1157.20180465. Sun YR. 1984. Selection of the optimum conditions for the sintering process of lepidolite limestone. Chinese Journal of Rare Metals, (5), 11–15. doi: 10.13373/j.cnki.cjrm.1984.05.003. Swain B. 2017. Recovery and recycling of lithium: A review. Separation and Purification Technology, 172, 388–403. doi: 10.1016/j.seppur.2016.08.031. Tadesse B, Makuei F, Albijanic B, Dyer L. 2019. The beneficiation of lithium minerals from hard rock ores: A review. Minerals Engineering, 131, 170–184. doi: 10.1016/j.mineng.2018.11.023. Talens PL, Villalba MG, Ayres RU. 2013. Lithium: Sources, production, uses, and recovery outlook. Jom, 65(8), 986–996. doi: 10.1007/s11837-013-0666-4. Tan B, Liu XH, Liu XD, Yi MG. 2021. Study on law of lithium extraction and impurity removal from spodumene leaching solution. Inorganic Chemicals Industry, 53(4), 56–60 (in Chinese with English abstract). doi: 10.11962/1006-4990.2020-0315. Tian J, Li T, Wang MC, Zhao HC, Shi JW. 2020. Research progress on extration process of lithium from lepidolite. Journal of Hubei University (Natural Science), 42(1), 56–60 (in Chinese with English abstract). doi: 10.3969/j.issn.1000-2375.2020.01.009. Tian QQ, Chen BZ, Chen Y, Ma LW, Shi XC. 2011. Roasting and leaching behavior of spodumene in sulphuric acid process. Chinese Journal of Rare Metal, 35(1), 118–123 (in Chinese with English abstract). doi: 10.3969/j.issn.0258-7076.2011.01.022. Tu T, Guo H, Cheng HJ, Qiu JM, Wang XZ, Liu QS. 2020. Phase reconstruction and kinetics of lithium extraction by spodumene-calcium oxide sintering process. Chemical Industry and Engineering Progress, 39(9), 3478–3486 (in Chinese with English abstract). doi: 10.16085/j.issn.1000-6613.2019-1878. USGS. 2022. Mineral Commodity Summaries 2022. doi: 10.3133/mcs2022. Vieceli N, Nogueira CA, Pereira MFC, Dias APS, Durão FO, Guimarães C, Margarido F. 2017. Effects of mechanical activation on lithium extraction from a lepidolite ore concentrate. Minerals Engineering, 102, 1–14. doi: 10.1016/j.mineng.2016.12.001. Vieceli N, Nogueira CA, Pereira MFC, Durão FO, Guimarães C, Margarido F. 2016. Optimization of lithium extraction from lepidolite by roasting using sodium and calcium sulfates. Mineral Processing and Extractive Metallurgy Review, 38(1), 62–72. doi: 10.1080/08827508.2016.1262858. Vieceli N, Nogueira CA, Pereira MFC, Durão FO, Guimarães C, Margarido F. 2018. Recovery of lithium carbonate by acid digestion and hydrometallurgical processing from mechanically activated lepidolite. Hydrometallurgy, 175, 1–10. doi: 10.1016/j.hydromet.2017.10.022. Vu H, Bernardi J, Jandová J, Vaculíková L, Goliáš V. 2013. Lithium and rubidium extraction from zinnwaldite by alkali digestion process: Sintering mechanism and leaching kinetics. International Journal of Mineral Processing, 123, 9–17. doi: 10.1016/j.minpro.2013.04.014. Vyas MH, Sanghavi JR, Seshadri, K. 1975. Lithium extraction from Indian lepidolite ores. Research and Industry, 20(2), 68–70. Wang D, Chen S, Liu XX, Cheng B, Ji QR. 2014. New process of lithium extraction from lepidolite by alkali dissolution. Inorganic Chemicals Industry, 46(9), 26–28 (in Chinese with English abstract). doi: 10.3969/j.issn.1006-4990.2014.09.006. Wang D, Chen S. 2020. Study on extraction process of lithium from lepidolite by high pressure steam. Inorganic Chemicals Industry, 52(2), 47–49 (in Chinese with English abstract). White GD, McVay TN. 1958. Some aspects of the recovery of lithium from spodume. Oak Ridge National Laboratory, Oak Ridge, Tennessee. doi: 10.2172/4352576. Wu XF, Yin ZH, Li XH, Wang ZX, Guo HJ. 2012. Extraction of lithium and postassium from Yichun lepidolite. Mining and Metallurgical Engineering, 32(3), 95–98. doi: 10.3969/j.issn.0253-6099.2012.03.026. Xi WW, Zhao YH, Ni P, Yao CY, Zhu YP, Zheng L, Yao, ZY, Wang TG. 2022. Main types, characteristics, distributions, and prospecting potential of lithium deposits. Sedimentary Geology and Tethyan Geology. doi: 10.19826/j.cnki.11009-13850.12022.04002. (in Chinese with English abstract). Xing P, Wang C, Zeng L, Ma B, Wang L, Chen Y, Yang C. 2019. Lithium extraction and hydroxysodalite zeolite synthesis by hydrothermal conversion of α-spodumene. ACS Sustainable Chemistry & Engineering, 7(10), 9498–9505. doi: 10.1021/acssuschemeng.9b00923. Xu SM, Wang XX. 1993. Study on pressure leaching process for the calcine of lepidolite by ammonium chloride. Rare Metals and Cemented Carbides, (4), 22–27 (in Chinese with English abstract). Yan QX, Li XH, Wang ZX, Wang JX, Guo HJ, Hu QY, Peng WJ, Wu XF. 2012d. Extraction of lithium from lepidolite using chlorination roasting–water leaching process. Transactions of Nonferrous Metals Society of China, 22(7), 1753–1759. doi: 10.1016/S1003-6326(11)61383-6. Yan QX, Li XH, Wang ZX, Wu XF, Guo HJ, Hu QY, Peng WJ, Wang JX. 2012c. Extraction of valuable metals from lepidolite. Hydrometallurgy, 117‒118, 116‒118. doi: 10.1016/j.hydromet.2012.02.004. Yan QX, Li XH, Wang ZX, Wu XF, Wang JX, Guo HJ, Hu QY, Peng WJ. 2012b. Extraction of lithium from lepidolite by sulfation roasting and water leaching. International Journal of Mineral Processing, 110‒111, 1‒5. doi: 10.1016/j.minpro.2012.03.005. Yan QX, Li XH, Yin ZL, Wang ZX, Guo HJ, Peng WJ, Hu QY. 2012a. A novel process for extracting lithium from lepidolite. Hydrometallurgy, 121‒124, 54‒59. doi: 10.1016/j.hydromet.2012.04.006. Yang HP, Liu L, Ding GF. 2019. Present situation and development trend of lithium resources in the world. Conservation and Ultilization of Minerals Resources, 39(5), 26–40 (in Chinese with English abstract). doi: 10.13779/j.cnki.issn1001-0076.2019.05.004. Yelatontsev D, Mukhachev A. 2021. Processing of lithium ores: Industrial technologies and case studies – A review. Hydrometallurgy, 201, 105578. doi: 10.1016/j.hydromet.2021.105578. Yi M, Zeng Q, Liu L. 2014. The prospects of industrialization of the lithium carbonate from lepidolite. Journal of Yichun College, 36(12), 59–60 (in Chinese with English abstract). doi: 10.3969/j.issn.1671-380X.2014.12.024. Yu F, Wang DH, Yu Y, Liu Z, Gao JQ, Zhong JA, Qin Y. 2019. The distribution and exploration status of domestic and foreign sedimentary-type lithium deposits. Rock and Mineral Analysis, 38(3), 354–364 (in Chinese with English abstract). doi: 10.15898/j.cnki.11-2131/td.201901180013. Zelikman AN, Krein OE, Sansonov GV. 1966. Metallurgy of rare metals (translated from Russian). Jerusalem: Israel Program for Scientific Translations, 234–245. Zhang JF. 2020. Current status of lithium extraction technology from spodumene. World Nonferrous Metals, 18, 130–133 (in Chinese with English abstract). doi: 10.3969/j.issn.1002-5065.2020.18.001. Zhang L, Yang HP, Liu L, Ding GF. 2020. Global Technology trends of lithium extraction. Conservation and Utilization of Mineral Resources, 40(5), 24–31 (in Chinese with English abstract). doi: 10.13779/j.cnki.issn1001-0076.2020.05.004. Zhang SJ, Cui LW, Kong LH, Jiang AL., Li JB. 2020. Summarize on the lithium mineral resources and their distribution at home and abroad. Nonferrous Metals Engineering, 10(10), 95–104 (in Chinese with English abstract). doi: 10.3969/j.issn.2095-1744.2020.10.015. Zhang XF, Tan XM, Liu WZ, Wang W, Zhang LZ. 2020. Current status and research progress of lithium extraction technology from ore. Conservation and Utilization of Mineral Resources, 40(5), 17–23 (in Chinese with English abstract). Zhao CL, Sun Z, Zheng XH, Gao WF, Zhang YL, Lin X. 2018. Research progress of lithium carbonate preparation and purification process. The Chinese Journal of Process Engineering, 18(1), 20–28 (in Chinese with English abstract). doi: 10.12034/j.issn.1009-606X.217234. Zhu JQ, Xu BJ, Song XW, Chen B. 2018. Process of extracting lithium technology. Metal Mine, (8), 62–69 (in Chinese with English abstract). doi: 10.19614/j.cnki.jsks.201808012. Zhu L, Gu HN, Yang YQ, Wen HJ, Wang N, Luo CG. 2020. Research progress of lithium extraction from clay-type lithium ore resources. Light Metals, (12), 8–13. doi: 10.13662/j.cnki.qjs.2020.12.003. Zhu ZH, Zhu CL, Wen XM, Zhuge Q, Ling BP. 2008. Progress in production process of lithium carbonat. Journal of Salt Lake Research, 16(3), 64–72 (in Chinese with English abstract). -

Access History

-

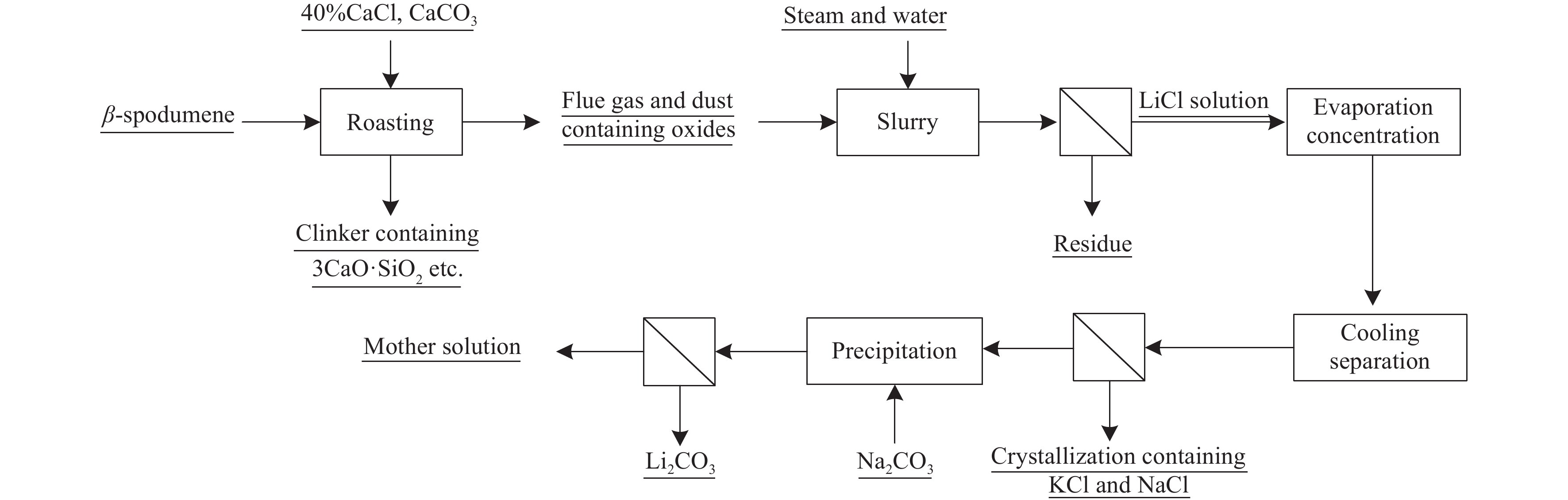

Figure 1.

Lithium production structure in China (2021).

-

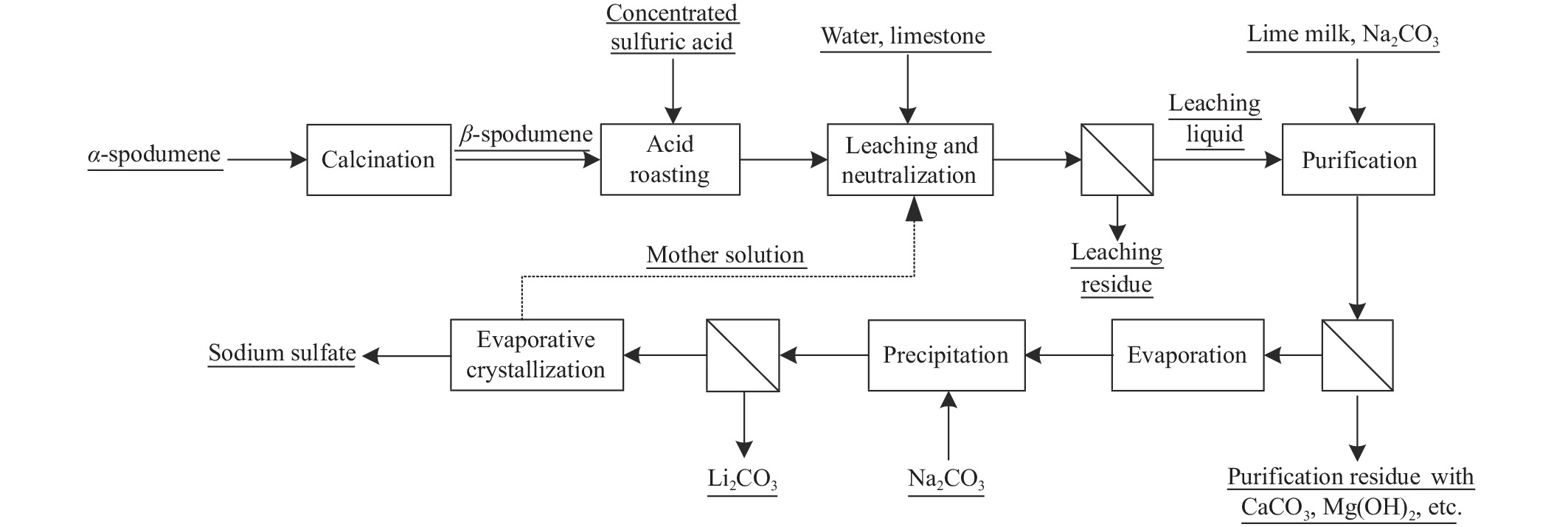

Figure 2.

Process flow sheet for extracting lithium from spodumene by the sulfuric acid method.

-

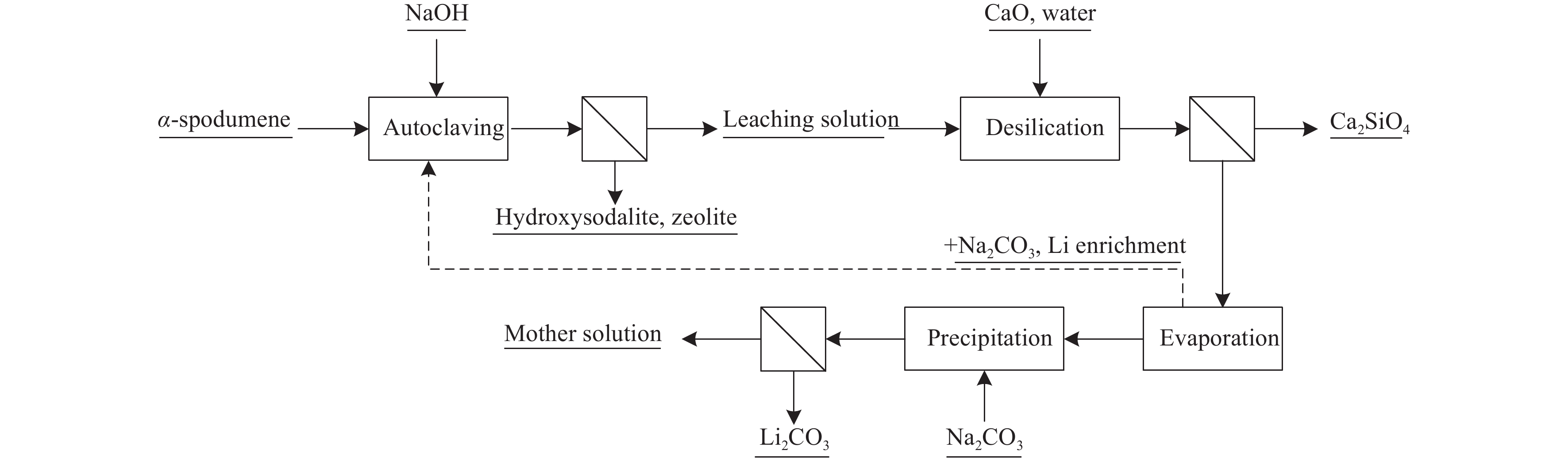

Figure 3.

Process of lithium extraction from spodumene by sodium hydroxide method (after Li H et al., 2019).

-

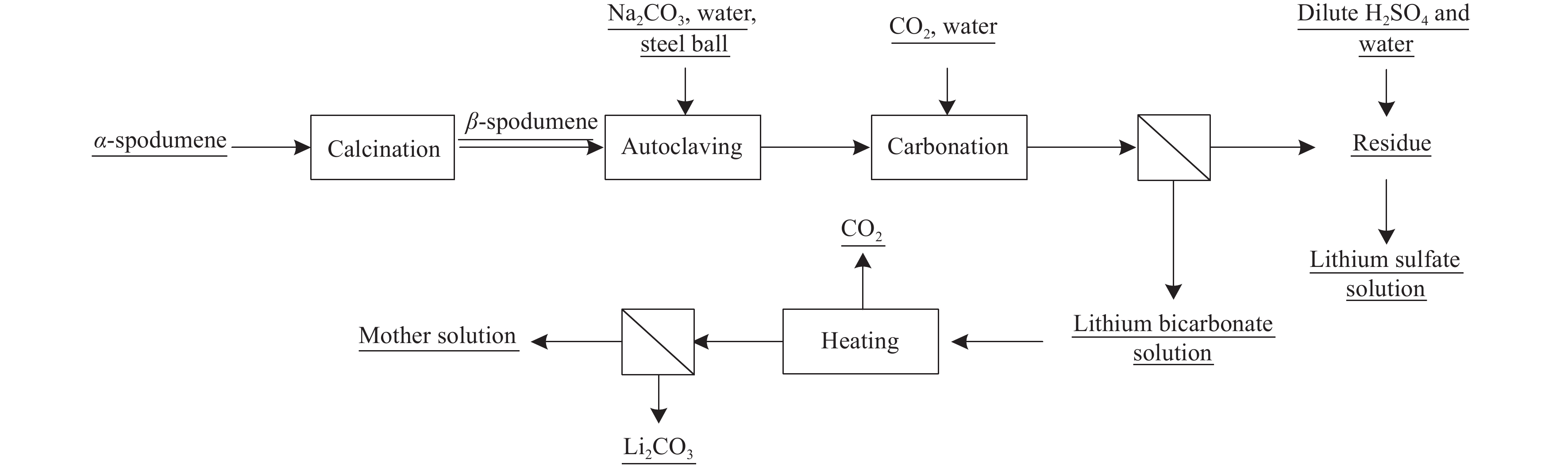

Figure 4.

Lithium recovery process of β-spodumene by sodium carbonate autoclave method (modified from Chen Y et al., 2011a, 2011b).

-

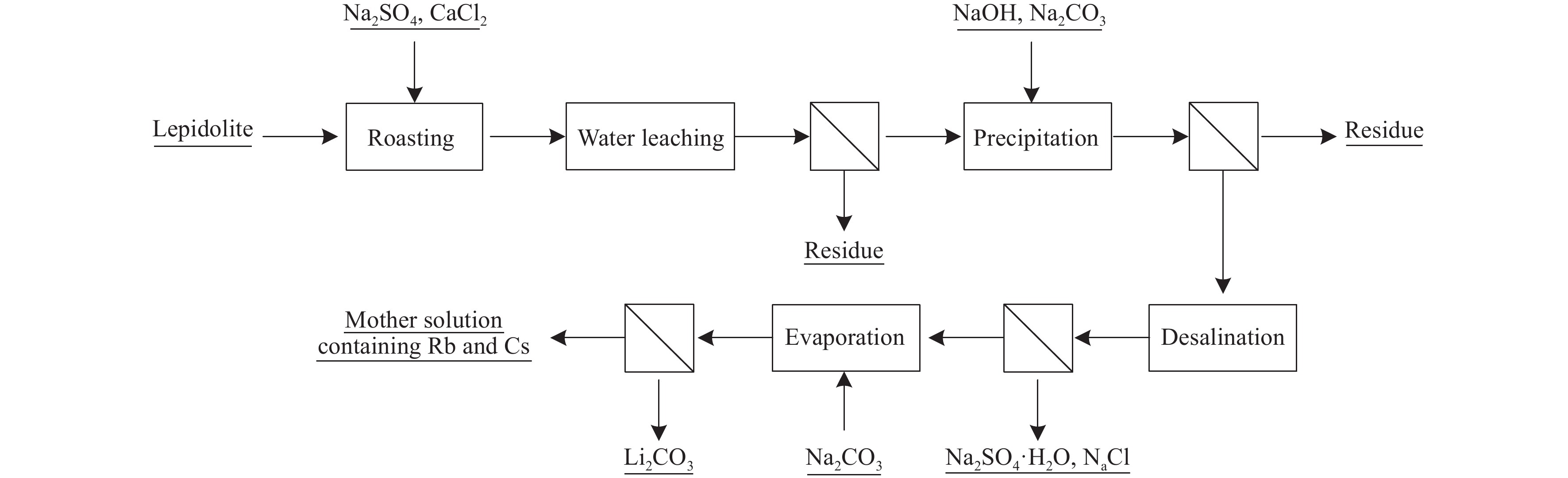

Figure 5.

Process for lithium recovery from lepidolite by sodium sulfate roasting method (modified from Li H et al., 2019; Yan QX et al., 2012c).

-

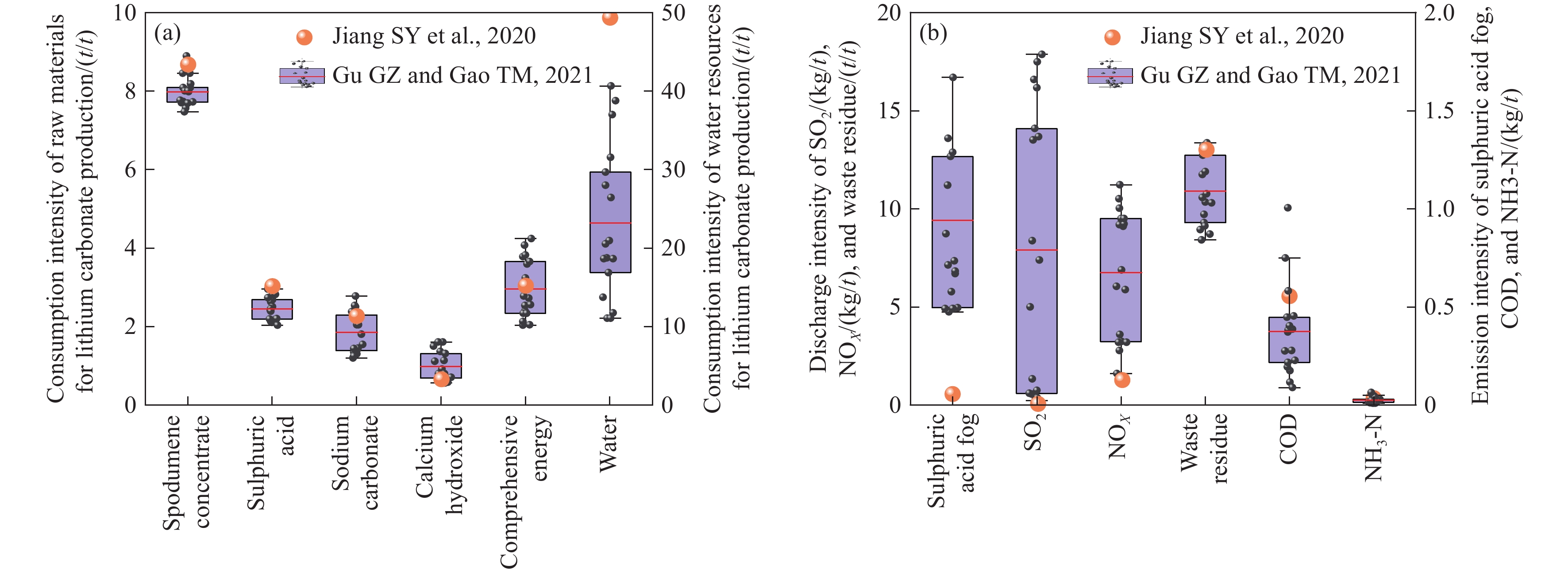

Figure 6.

Process flow chart of lithium carbonate production by chlorination roasting method (modified from Zhu ZH et al., 2008).

-

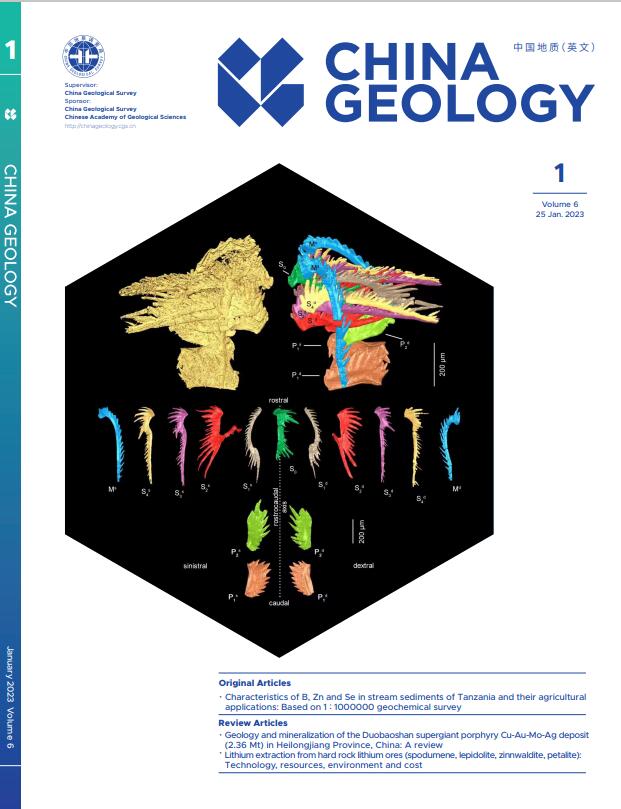

Figure 7.

Resource consumption (a) and pollutant emission (b) of lithium extraction from spodumene by the sulfuric acid method.

-

Figure 8.

Comparison of production cost between spodumene sulfuric acid and lepidolite sulfate method.

DownLoad:

DownLoad: