| Citation: | Jing Zeng, Wen-wei Xie, Bei-bei Kou, Jing-an Lu, Xing-chen Li, De-jun Cai, Hao-xian Shi, Ke-wei Zhang, Hua-qing Liu, Jin Li, Bo Li, 2023. Lateral bearing characteristics of subsea wellhead assembly in the hydrate trial production engineering, China Geology, 6, 455-465. doi: 10.31035/cg2022057 |

Lateral bearing characteristics of subsea wellhead assembly in the hydrate trial production engineering

-

Abstract

Conductor and suction anchor are the key equipment providing bearing capacity in the field of deep-water drilling or offshore engineering, which have the advantages of high operation efficiency and short construction period. In order to drill a horizontal well in the shallow hydrate reservoir in the deep water, the suction anchor wellhead assembly is employed to undertake the main vertical bearing capacity in the second round of hydrate trial production project, so as to reduce the conductor running depth and heighten the kick-off point position. However, the deformation law of the deep-water suction anchor wellhead assembly under the moving load of the riser is not clear, and it is necessary to understand the lateral bearing characteristics to guide the design of its structural scheme. Based on 3D solid finite element method, the solid finite element model of the suction anchor wellhead assembly is established. In the model, the seabed soil is divided into seven layers, the contact between the wellhead assembly and the soil is simulated, and the vertical load and bending moment are applied to the wellhead node to simulate the riser movement when working in the deep water. The lateral bearing stability of conventional wellhead assembly and suction anchor wellhead assembly under the influence of wellhead load is discussed. The analysis results show that the bending moment is the main factor affecting the lateral deformation of the wellhead string; the anti-bending performance from increasing the outer conductor diameter is better than that from increasing the conductor wall thickness; for the subsea wellhead, the suction anchor obviously improves the lateral bearing capacity and reduces the lateral deformation. The conduct of the suction anchor wellhead assembly still needs to be lowered to a certain depth that below the maximum disturbed depth to ensure the lateral bearing stability, Thus, a method for the minimum conductor running depth for the suction anchor wellhead assembly is developed. The field implementations show that compared with the first round of hydrate trial production project, the conductor running depth is increased by 9.42 m, and there is no risk of wellhead overturning during the trial production. The method for determining the minimum conductor running depth in this paper is feasible and will still play an important role in the subsequent hydrate exploration and development.

-

-

References

Chang YJ, Wang J, Ji JQ, Li JY, Xu LB, Sheng LX, Qiao C. 2019. A semi decoupled analysis model of subsea wellhead based on local equivalent method. Journal of China University of Petroleum (Edition of Natural Science), 43(03), 129–137 (in Chinese with English abstract). doi: 10.3969/j.issn.1673-5005.2019.03.015. Deng S, Geng HR, Zhao HY, Zhu S, Ji MN, Xia YC. 2019. Static performance analysis of riser-conductor system based on whole method in deep water drilling. Energy Engineering, 04, 13−21,doi: 10.16189/j.cnki.nygc.2019.04.004. Guo R. 2019, Mechanical Behavior Analysis of Conductor Anchor Node, Beijing, China University of Petroleum (Beijing), Master thesis. 1−62 (in Chinese with English abstract). Guan ZC, Su KH, Su YN. 2009. Analysis on lateral load-bearing capacity of conductor and surface casing for deep-water drilling. Acta Petrolei Sinica, 30(2), 285–290 (in Chinese with English abstract). doi: 10.3321/j.issn:0253-2697.2009.02.023. Li B, Kou BB, Li B, Li J, Zeng J, Niu Q, Shao YT, Zhang KW, Yu HY, Wang YS. 2022. Application of wellhead suction anchor technology in the second production test of natural gas hydrates in the South China Sea. China Geology, 5(2), 293–299. doi: 10.31035/cg2022027. Li WL, Gao DL, Yang J, 2019. Challenges and prospect of the drilling and completion technologies used for the natural gas hydrate reservoirs in sea areas. Oil Drilling & Production Technology (in Chinese with English abstract), 41(6), 681−689. doi: 10.13639/j.odpt.2019.06.001. Li YL, Liu LL, Jin YR, Wu NY. 2021. Characterization and development of natural gas hydrate in marine clayey-silt reservoirs: A review and discussion. Advances in Geo-Energy Research, 5(1), 5–86. doi: 10.46690/ager.2021.01.08. Liu JL, Chen LW, Wang JL, Wang DL. 2016. Horizontal bearing capacity of suction anchor foundation in ocean engineering. Journal of Civil Engineering and Management. 33(02), 1–5 (in Chinese with English abstract). doi: 10.3969/j.issn.2095-0985.2016.02.001. Liu QY, Qing S, Mao LJ, Wang GR. 2019. Analysis of Influencing Factors on Carrying Capacity of Deep-water Conductors. Petroleum Drilling Techniques, 47(05), 49–56. doi: 10.11911/syztjs.2019099. Liu SJ, Zhou JL, Yang J, Wang PS, Xie RJ. 2013. Study on the driving depth prediction and control of offshore drilling conductor, China Offshore Oil and Gas, 25(6), 75−81+126 (in Chinese with English abstract). doi: CNKI:SUN:ZHSD.0.2013-06-014. Mcclelland B, Focht JA. 1956. Soil Modulus for Laterally Loaded Piles. ASCE Soil Mechanics and Foundation Division Journal, 82(4), 1−22. doi: 10.1061/TACEAT.0007599. Pilisi N, Whitney B, Kawamura Y. 2012. Designing the World’s Deepest Offshore Well to Drill and Core the Earth’s Mantle. doi: 10.4043/23202-MS. Qin XW, Lu C, Wang PK, Liang QY. 2022. Hydrate phase transition and seepage mechanism during natural gas hydrate production tests in the South China Sea: A review and prospect. Geology in China, 49(3), 749–769 (in Chinese with English abstract). Su KH. 2009. Analysis on Mechanical Stability of Subsea Wellhead and Bearing Capacity of Conductor for Deep-water drilling, China University of Petroleum, Ph. D theis, 1–166 (in Chinese with English abstract). Shaibu R, Sambo C, Guo BY, Dudun A. 2021. An assessment of methane gas production from natural gas hydrates: Challenges, technology and market outlook. Advances in Geo-Energy Research, 5(3), 318–332. doi: 10.46690/ager.2021.03.07. Tang HX, Luo JF, Ye JH, Chen WJ, Chang YJ, Chen GM. 2011. Method of Design of Conductor Setting Depth for Ultra-deep-water Jetting Drilling in South China Sea. Journal of Oil and Gas Technology, 33(3), 147–151+170 (in Chinese with English abstract). doi: 10.3969/j.issn.1000-9752.2011.03.034. Wolters JG, Marcon NV. 1973. Lateral Load Capacity of Piles in Offshore Structures. Journal of Petroleum Technology, 25(04), 487–498. doi: 10.2118/3761-PA. Wang YB, Gao DL, Fang J. 2014. Numerical analysis of bearing capacity of deep-water conductor with consideration of different contract interface models between pile and soil. China Offshore Oil and Gas, 26(5), 76–82 (in Chinese with English abstract). Yang C, Liu XG, Liu YJ, Yang J, Wu Y, Wei Q. 2011. Analysis on overrall mechanical properties of drilling riser for exploratory well in Bohai Oilfield. Fault-Block Oil and Gas Field, 18(5), 666–668 (in Chinese with English abstract). Yang J, Wang ZJ, Zhou JL, Liu SJ, 2003. Application and calculation of Ultimate load-bearing capacity of Sea floor earth in DF 1-1 Oilfield. China Offshore Oil and Gas (Engineering), 15(01), 21−23+38-61 (in Chinese with English abstract). doi: 10.3969/j.issn.1673-1506.2003.01.005. Ye JL, Qing XW, Xie WW, Lu HL, Ma JB, Qiu HJ, Liang JQ, Lu JA, Kuang ZG, Lu C. 2020. Main progress of the second gas hydrate trial production in the South China Sea, China Geology, 47(3), 557−568. doi: 10.12029/gc20200301. Zhu P, Ma T, Chen M, Yin L, Zhang C, Wei W, Teng Z. 2022. Petrophysical experiment-based evaluation method for the saturation of gas hydrate. Unconventional Resources, 2, 158–169. doi: 10.1016/j.uncres.2022.09.003. -

Access History

-

Figure 1.

Schematic diagram of conventional deep-water wellhead assembly (a) and deep-water wellhead assembly with suction anchor (b).

-

Figure 2.

Suction anchor of second natural gas hydrate trial production.

-

Figure 3.

FEA simulation analysis model of wellhead-soil body.

-

Figure 4.

Simulation analysis results of lateral bending deformation of wellhead assembly.

-

Figure 5.

(a)‒Effect of wellhead bending moment on conductor bending moment distribution; (b)‒Effect of wellhead bending moment on lateral deformation of conductor; (c)‒Effect of vertical wellhead load on conductor bending moment distribution; (d)‒Effect of wellhead vertical load on lateral deformation of conductor.

-

Figure 6.

(a)‒Effect of string structure combination on bending moment distribution of conductor; (b)‒Effect of string structure combination on lateral deformation of conductor.

-

Figure 7.

(a)‒Effect of running depth of 3.81 cm conductor section on bending moment distribution; (b)‒Effect of running depth of 3.81 cm conductor section on lateral deformation.

-

Figure 8.

Lateral deformation simulation results of wellhead device with suction anchor.

-

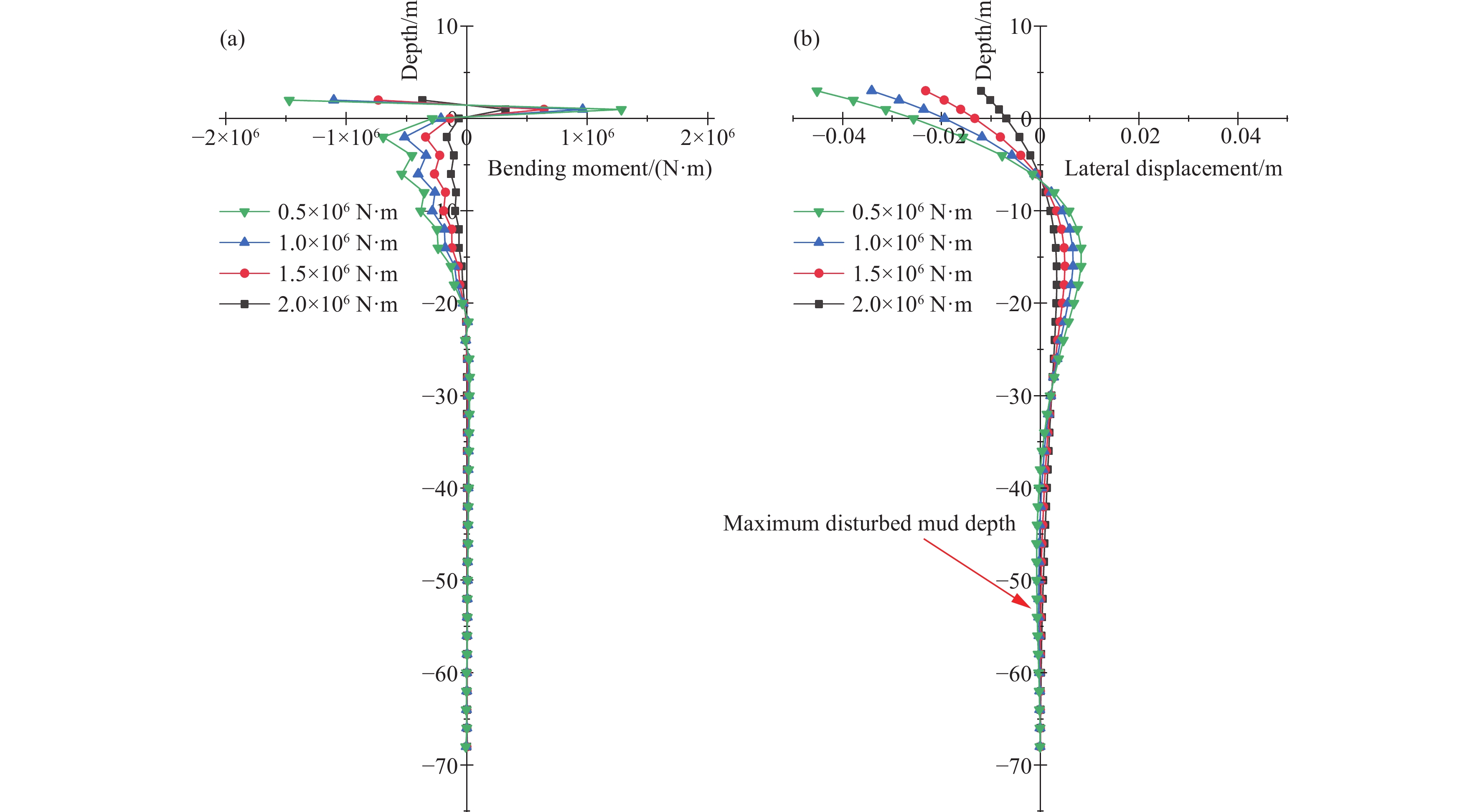

Figure 9.

(a)‒Effect of bending moment on bending moment of suction anchor wellhead assembly; (b)‒Effect of bending moment on deformation of suction anchor wellhead assembly

-

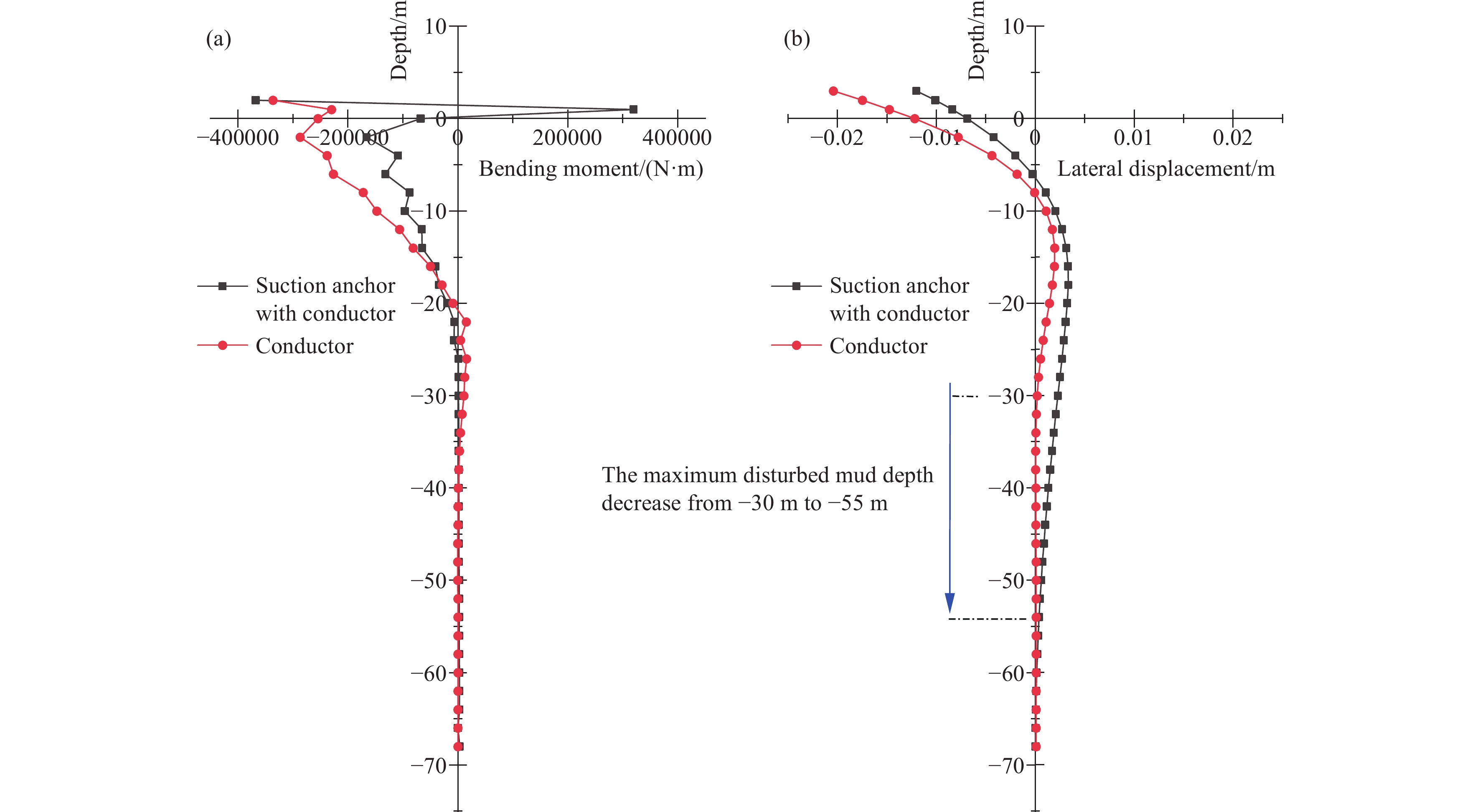

Figure 10.

Comparison of bending moment of wellhead assembly

DownLoad:

DownLoad: