| Citation: | Yong-yi Zhu, Wen-shi Wang, Xiao-ming Wu, Heng-chun Zhang, Jie Xu, Jia Yan, Long-long Cao, Heng-qian Ran, Jin-chang Zhang, 2018. Main technical innovations of Songke Well No.2 Drilling Project, China Geology, 1, 187-201. doi: 10.31035/cg2018031 |

Main technical innovations of Songke Well No.2 Drilling Project

-

Abstract

Songke Well No.2, one of the main part of the scientific drilling project in Songliao Basin, which was drilled 7018 m and acquired the part of cores continuously from the Low Cretaceous to the Carboniferous and the Permian from the 2843 m deep, can be considered as the deepest continental drilling project in Asia. Aiming at the features of longer well sections, larger diameters and multiple spud-ins for coring of Songke Well No.2, this project broke through the “coring in small diameter and reaming in large diameter” spud-in drilling-completion procedures which are always used in large-diameter-well coring for continental scientific drilling projects in domestic and overseas and the drilling method of short-single-cylinder roundtrip footage. At the same time, “coring in the same diameter and completing drilling at one single diameter” was achieved at all φ311 mm and φ216 mm coring sections of more than one thousand meters long, high-efficient operation with “drilling long footage with drill tools combined in multi-cylinders” was achieved at deep coring section. Four world drilling records were created which include more than a thousand meters continuous coring at φ311 mm, and the footage per roundtrip footage at φ311 mm, φ216 mm and φ152 mm is all more than 30 m, all of these breakthroughs reduced at least 300 days for this project; moreover, considering the characteristics of formations that the geothermal gradient is high in the drilled sections and the inside-well temperature is over 240°C after drilling completion, a formate-polymer water-based mud system was developed by compounding attapulgite and sodium bentonite and by adding independently developed high-temperature stabilizer, which can provide critical technical support for successful well completion at 7018 m in the super-high-temperature environment It is the first time that the water-based mud is operated at the working temperature higher than 240°C in China; Besides, considering the high-quality requirement on cores imposed by the project, the method “mechanical cored is charge” to discharge core nondestructively on the ground was worked out, and more than 4000 m scatheless cores were discharged out of the drill pipes while maintaining original stratum structures.

-

-

References

[1] Wang PJ, Liu HB, Ren TG, Wang XJ, Wang SX, Qu XJ, Meng QA, Huang YJ, Huang QH, Gao YF, Wang CS. 2017. How to choose a right drilling site for the ICDP Cretaceous Continental Scientific Drilling in the Songliao Basin (SK2). Earth Science Frontiers, 1(1), 216–228. [2] Elward-Berry, Darby B. Rheologically stable, nontoxic. High-temperature water-based drilling fluid. 1997. SPE 24589 [3] Engeser B.1996. Drilling technology report on deep drilling program in the Federal Republic of Germany.96−99,247−253,314−317,437−460. [4] Hu XY, Wang X, Zhang LJ, et al. 2016. Research on Ultra-High Temperature Water Based Drilling Fluid. Advances in Fine Petrochemical, 17(6), 8–12. [5] Huang LJ. 2011. Design Principles and Application of Ultra-deep well Mud. 2011−01−14 [6] Jia JL, Xu D, Fan LS, Duan XQ. 2012. Drilling Technology in WFSD-2 of Wenchuan Earthquake Fault Scientific Drilling Project. Exploration Engineering (Rock & Soil Drilling and Tunneling), 39(9), 6–11. [7] Kazlowski EA.1989. kola superdeep borehole (last). Beijing, Geological Publishing House, 88−89,120−124,169 [8] Konno M. 1993. High Temperature Mud System for Deep Well Drilling in Japan. Association of Petroleum Engineers Journal, 58(5), 387–392. [9] Li GR, Xue YZ, Liu BF. 2009. High Temperature High Density Drilling Fluid Technology for the Forth Interval of Shengke-1. Drilling Fluid & Completion Fluid, 26(2), 12–15. [10] Lin ZQ, Yang GS, Zhang J. 2007. Application of Coring with Formation Kept Techniques in SLCORE-1. Exploration Engineering (Rock and Soil Drilling and Tunneling), 7, 49–51. [11] Liu DH, Li Zhan W, Bi QC, Song YL. 1998. Brief introduction of Russian CГ-3 ultra-deep well drilling in Kola Peninsula,. Oil Drilling & Production Technology, 20(6), 4–45. [12] Morihiro S. 1994. Development of the Mud System for High Temperature. Association of Petroleum Engineers Journal, 59(2), 129–135. [13] Prater T. 1999. Fluid Systems key to Record success. Amer Oil Gas Rep, 42(8), 79–84. [14] Qu XJ. 2015. Several key geological constrains on the Continental Scientific Drilling of Cretaceous Songliao Basin (SK2), Jilin, Jilin University,1−140 [15] Sun ZW, He ZK, Liu X. 2009. The Ultra High Temperature Water Based Drilling Fluid Technology for Well Bishen-1. Drilling Fluid & Completion Fluid, 26(3), 9–11. [16] Thaemlitz CJ, Patel AD, Coffin G. New Environmentally Safe High-temperature Water-based Drilling-fluid System. 1999. New Environmentally Safe High-temperature Water-based Drilling-fluid System. SPE Drilling & Completion, 14(3), 185–189. [17] Wang CS,Feng ZQ, Wang PJ, Kong FJ, Feng ZH, Ren YG, Yang GS, Wan XQ, Hang YJ, Zhang SH. 2014. Initial Report of Continental Scientific Drilling Project of the Cretaceous Songliao Basin (SK1). Beijing. Science Press.41−45 [18] Wang D, Zhang W, Zhang XX. 2007. Drilling Technology of CCSD−1. Beijing. Science Press. 131, 255 [19] Wang ZH. 2011. Status and Development Trend of Ultra-High Temperature and High-Density Drilling Fluid at Home and Abroad. Petroleum Drilling Techniques, 39(2), 1–5. [20] Xu J, Wu XM, Zhu YY. 2015. Laboratory on Ultra High Temperature Water Based Mud. Drilling Fluid & Completion Fluid, 32(1), 10–13. [21] Xu J. 2015. Research on Ultra−High Temperature Water−Based Drilling Fluid and its Rhelogical model−−Take the Case of Well CCSD−SK2. China University of Geosciences [22] Xu TT. 1991. The Development of Deep Well Mud Abroad in Eighties Last Century. Drilling Fluid & Completion Fluid, 8(supplement), 29–45. [23] Zhang JC, Xie WW. 2010. Status of Scientific Drilling Technology for Ultra-Deep Well. Acta Geologica Sinica, 84(06), 887–894. [24] Zhang W. 1999. Drilling technology and construction in Hawaii Scientific Drilling Project. Exploration Engineering (Rock & Soil Drilling and Tunneling), (4), 52–53. [25] Zhu HY, Zhu YY, Zhang WS, Yu SP, Qi XZ. 2012. Construction Technology and Experience of WFSD-3 Hole of Wenchuan Earthquake Fault Scientific Drilling Project. Exploration Engineering (Rock & Soil Drilling and Tunneling), 39(9), 12–17. [26] Zhu YY, Wang WS. 2008. Coring Drilling Technology in Well-1 (main shaft) of Songliao Scientific Drilling. Exploration Engineering (Rock & Soil drilling and Tunneling), 35(9), 1–5 (in Chinese with English abstract). [27] Zhu YY, Wang WS. 2008. Summery on China Cretaceous Scientific Drilling Engineering in Well-1 of Songliao Scientific Drilling. Exploration Engineering (Rock & Soil drilling and Tunneling), 35(3), 1–4 (in Chinese with English abstract). [28] Zhu YY. 2006. Development and Application of KZ Single Rotary and Double Tube Core Barrel. Petroleum Drilling Techniques, 34(3), 19–22 (in Chinese with English abstract). -

Access History

-

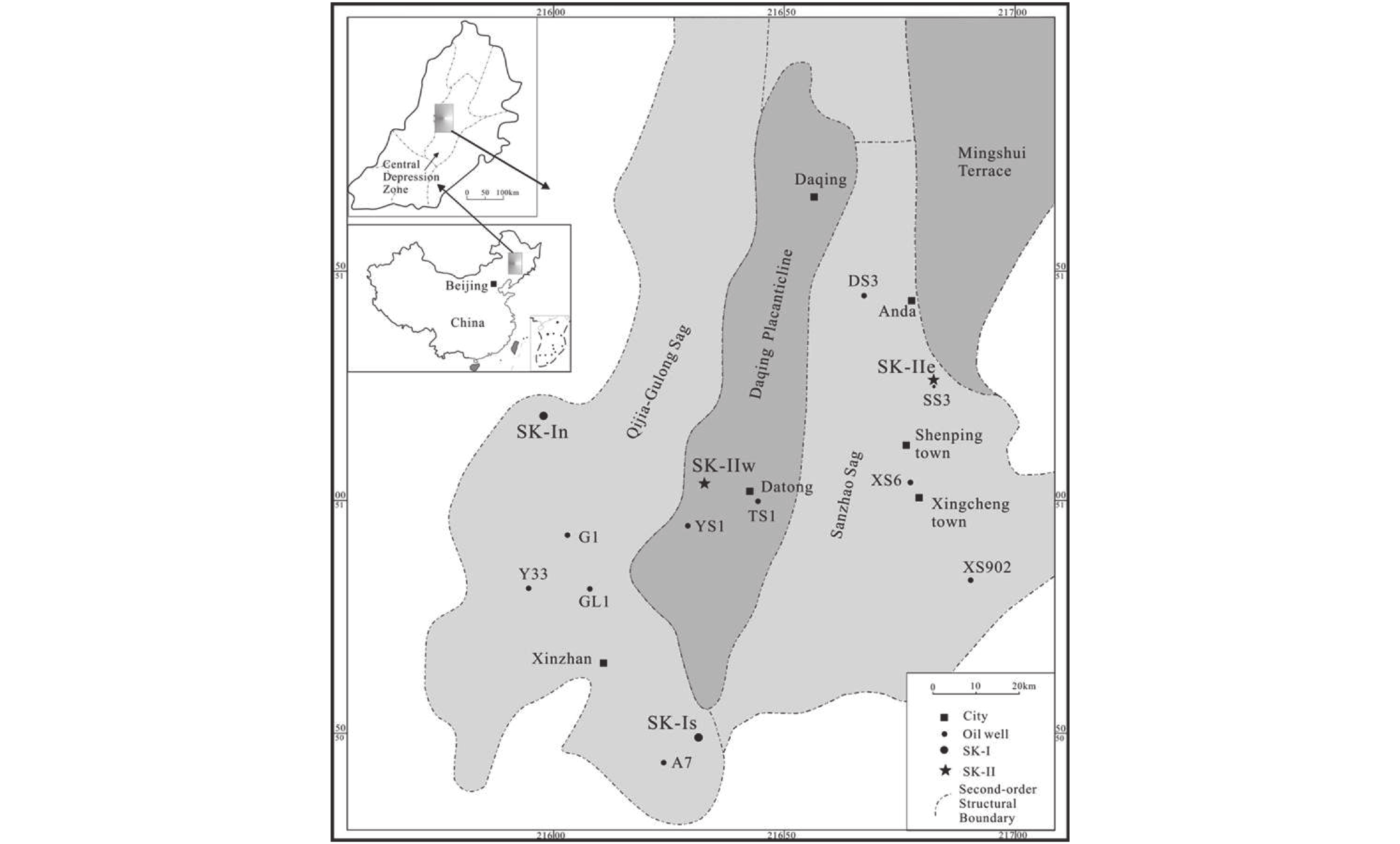

Figure 1.

Base map of "two wells and four holes" locations during the scientific drilling in Songliao Basin.

-

Figure 2.

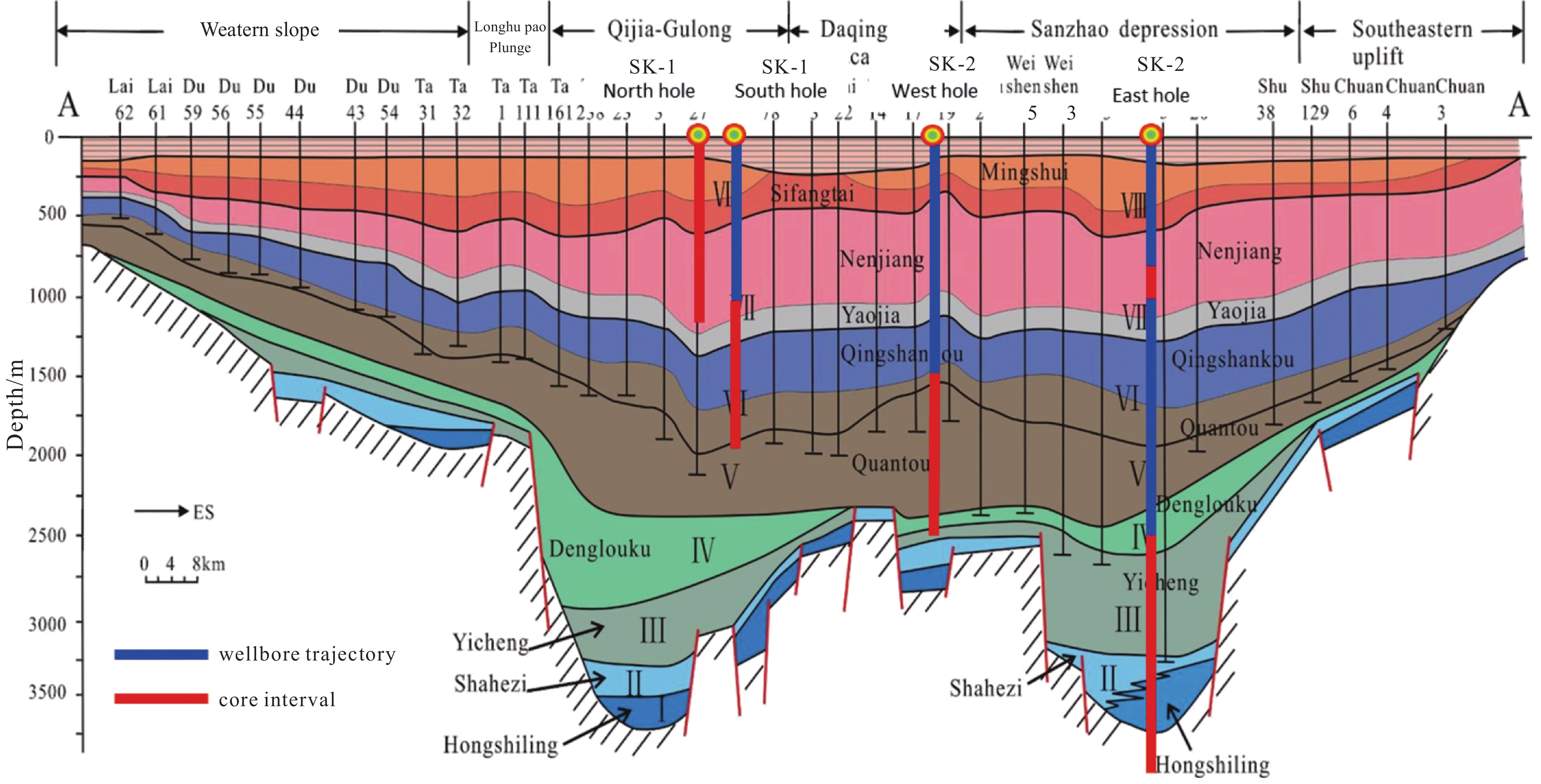

Cross section of the well positions in Songliao Basin.

-

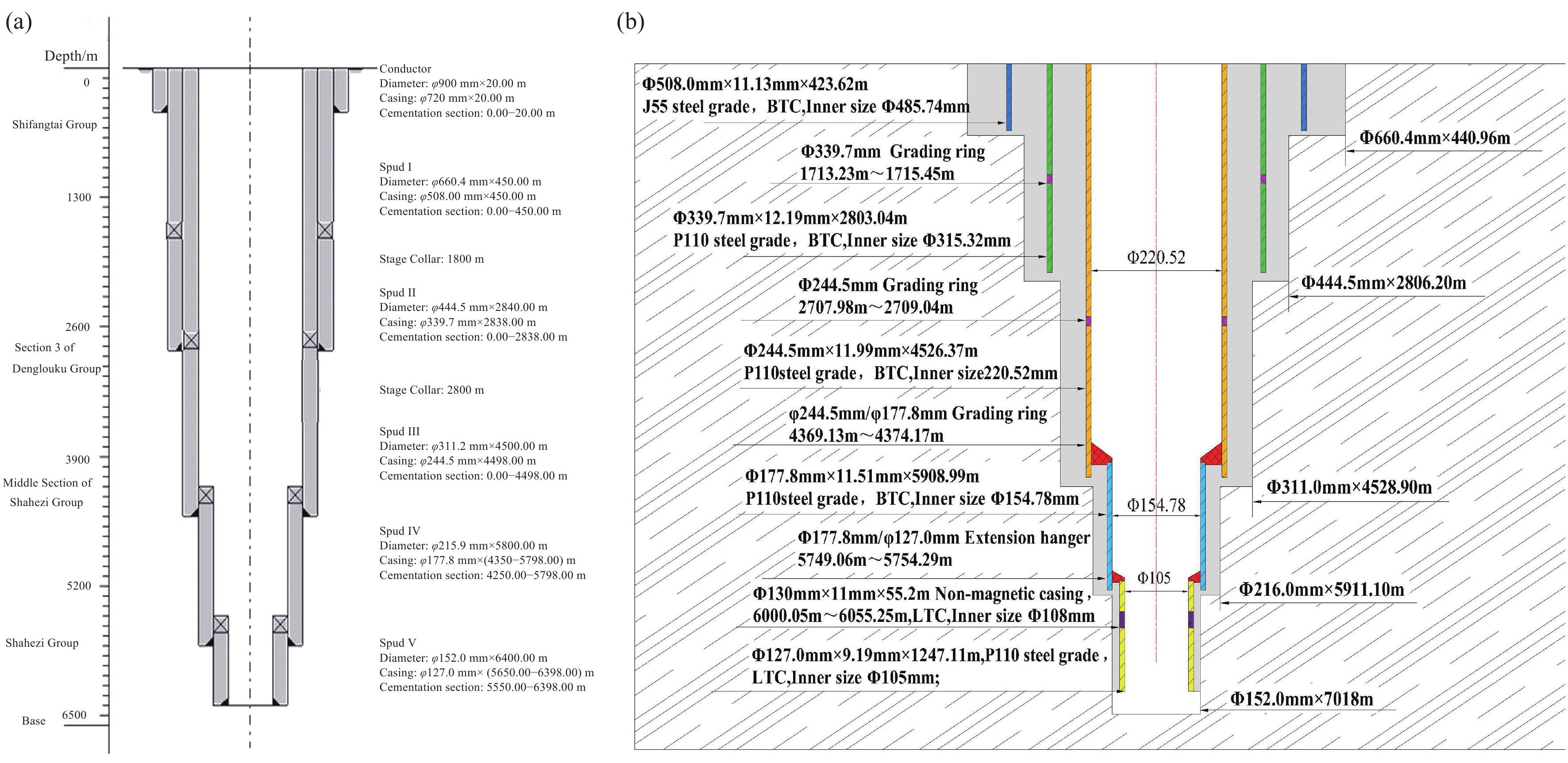

Figure 3.

(a) The original design of the borehole structure of CCSD-SKII. (b) Borehole structure of well completion of SK-II.

-

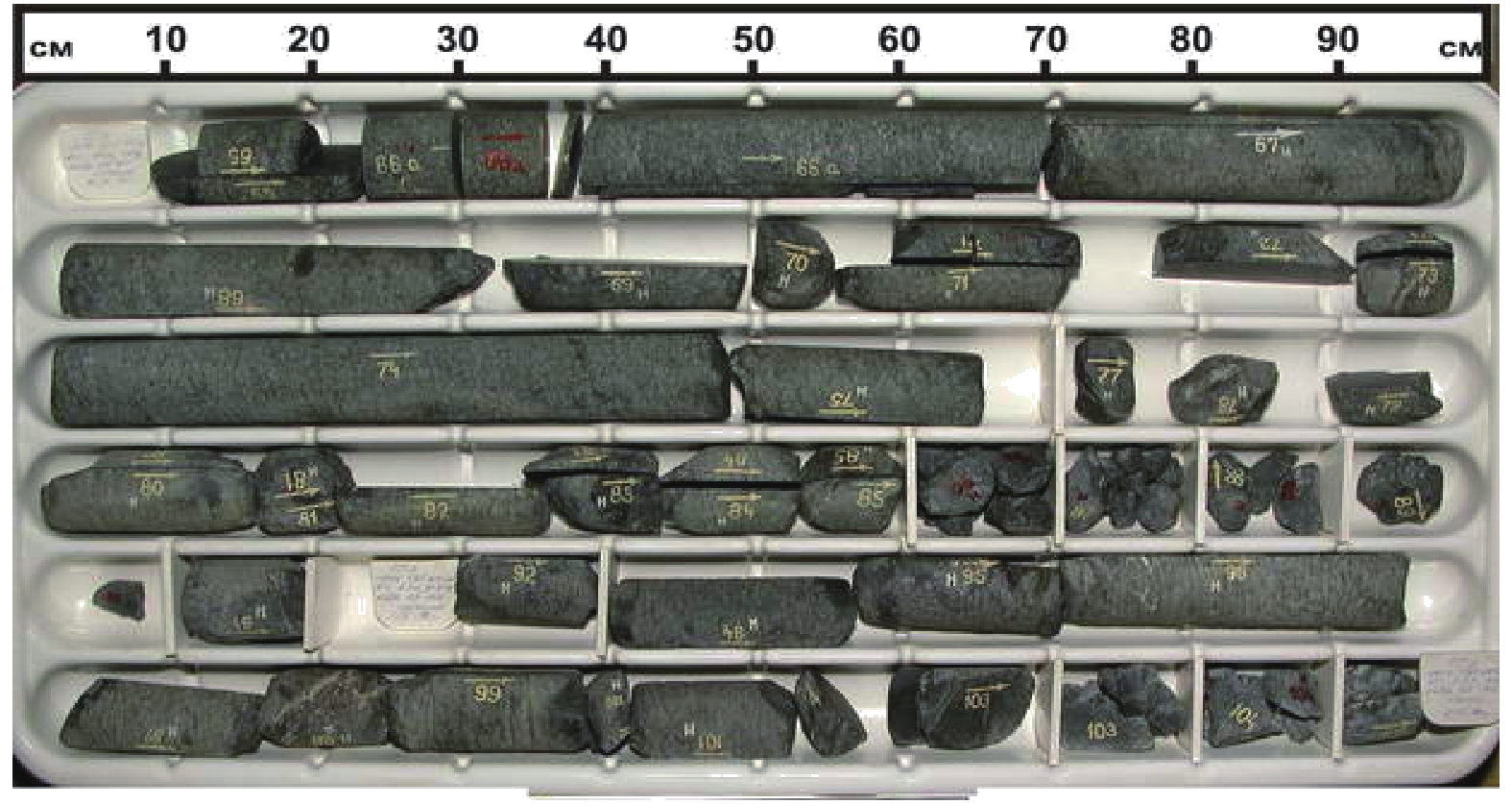

Figure 4.

The cores drilled by rock bit in Kola-III.

-

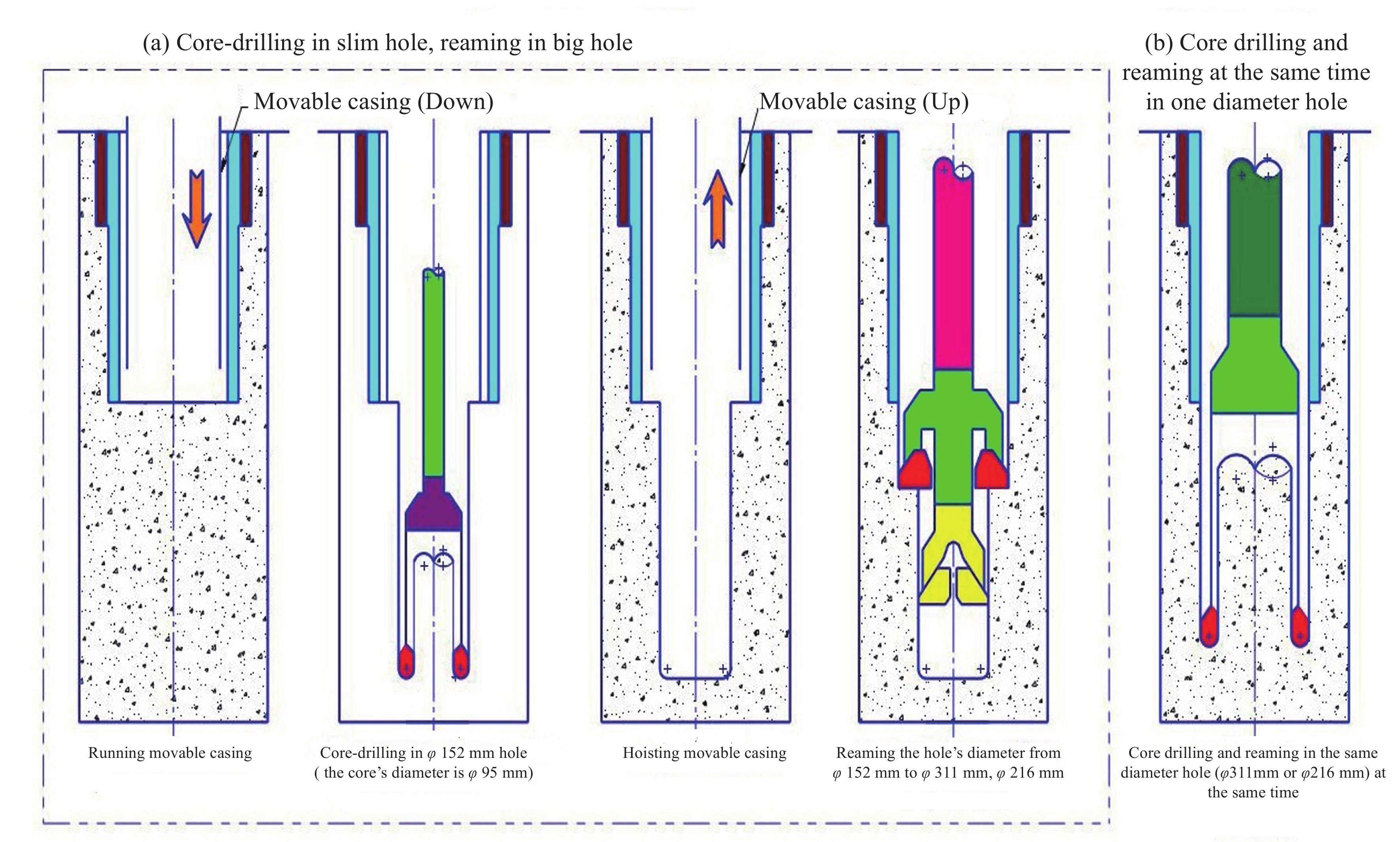

Figure 5.

Steps of two different core-drilling methods in large diameter interval.

-

Figure 6.

(a), (b) Seventy-two reeds from the coadjutors failed into CCSD-1 while hoisting movable casing. (c), (d) The guiding part of pilot bit failed into CCSD-1. (e) KT-type drilling tools.

-

Figure 7.

Cores drilled by large-diameter drilling tools in the equal borehole. (a) φ214 mm cores drilled from the Spud III of CCSD-SKII. (b) φ124 mm cores drilled from the Spud IV of CCSD-SKI.

-

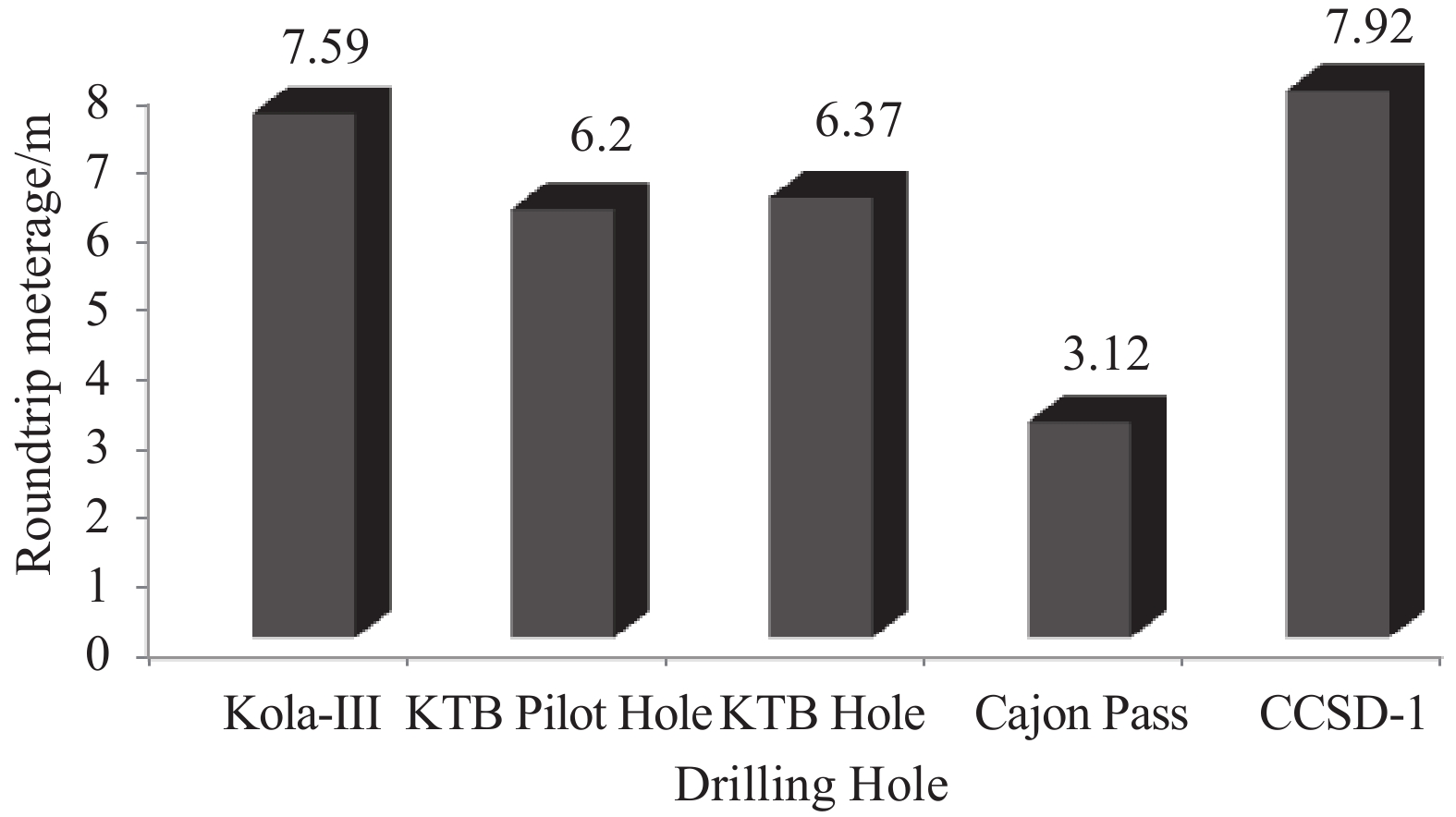

Figure 8.

The average roundtrip meterage in different scientific drilling projects. The KTB's data is based on core-drilling by rock bit, and CCSD-1 data is based on hydro-percussive tools.

-

Figure 9.

KT type core-drilling tools assembled by three long core barrels.

-

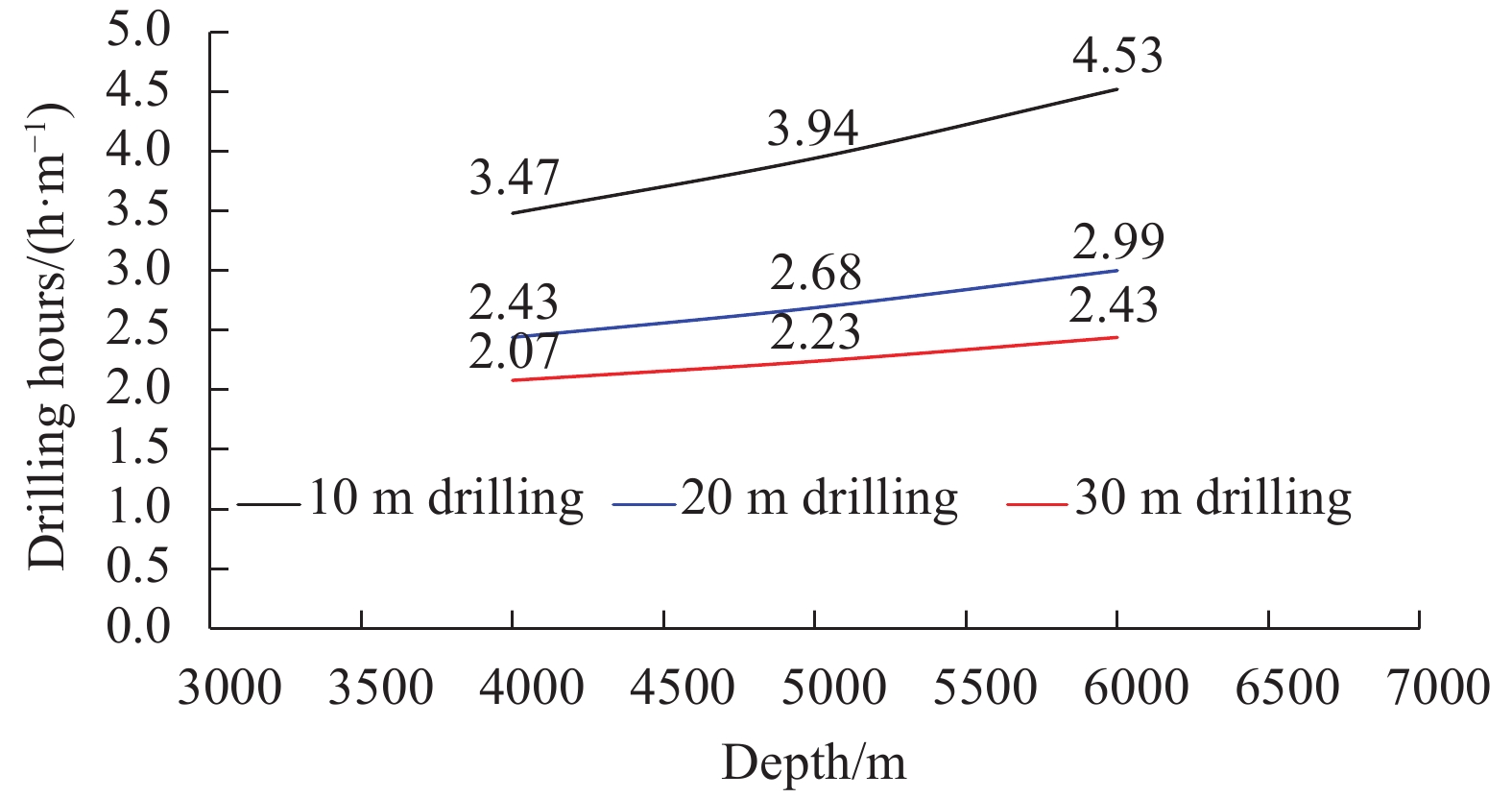

Figure 10.

The comparison of the efficiencies on three different lengths of cores drilled in a single roundtrip, 10 m, 20 m, 30 m.

-

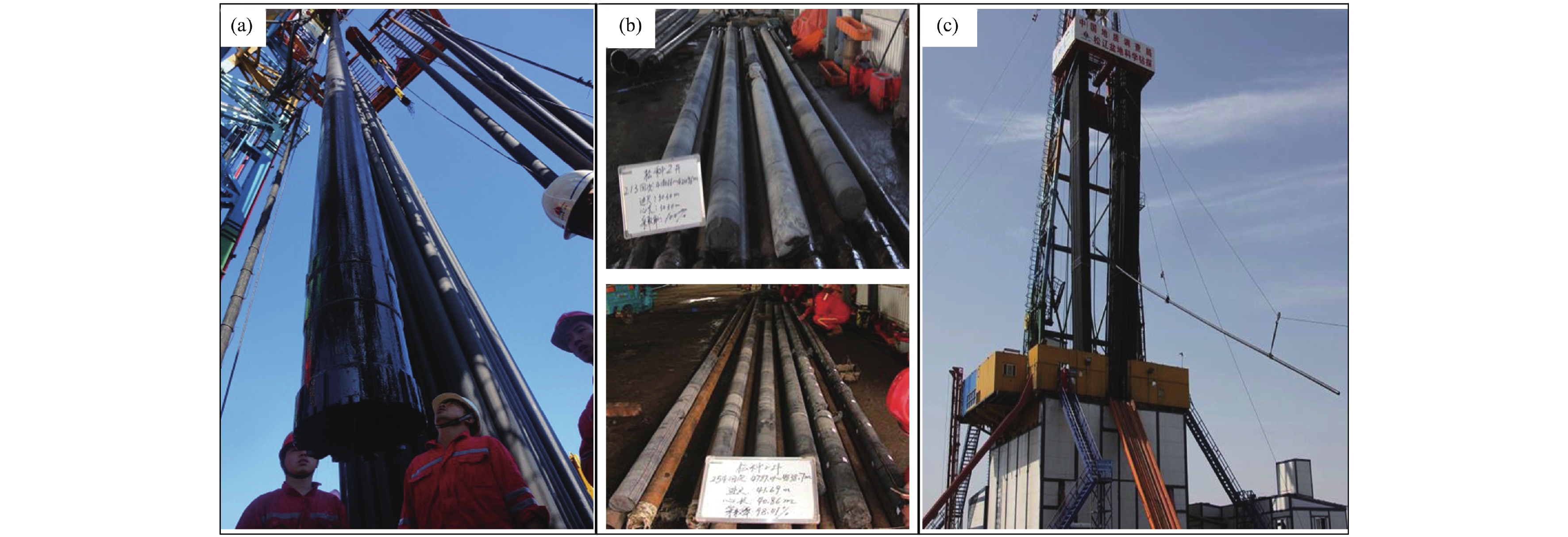

Figure 11.

The extended core drilling tools and core samples (a) The moment of three core barrels drilling tool lifted up from the borehole. (b) Cores. (c) The extended core-drilling platform.

-

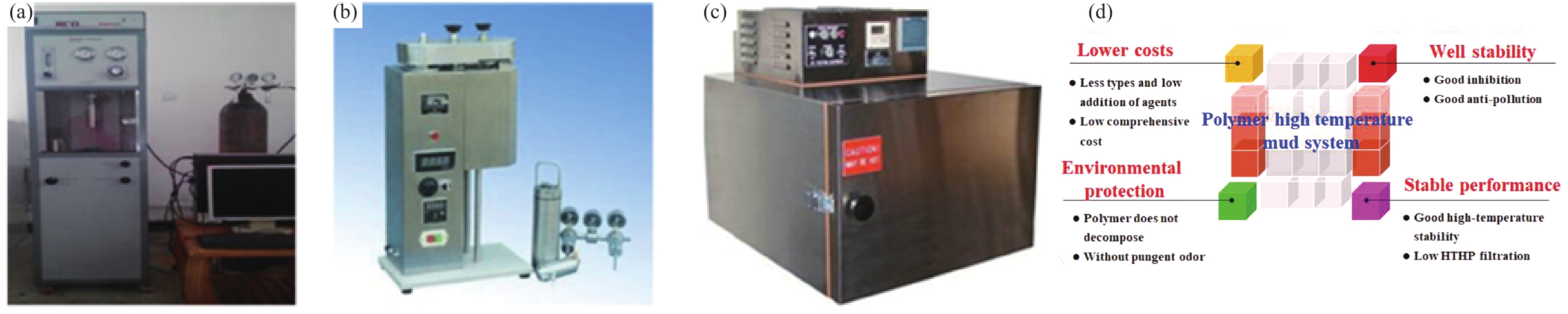

Figure 12.

Some testing instruments for high temperature and high-pressure properties of mud. (a) FANN-50SL HTHP rheometer. (b) GGS71-1A High temperature and high pressure dynamic filter. (c) OFI 173-00-1 High temperature roller furnace. (d) requirements of ultra-high temperature polymer water-based mud.

-

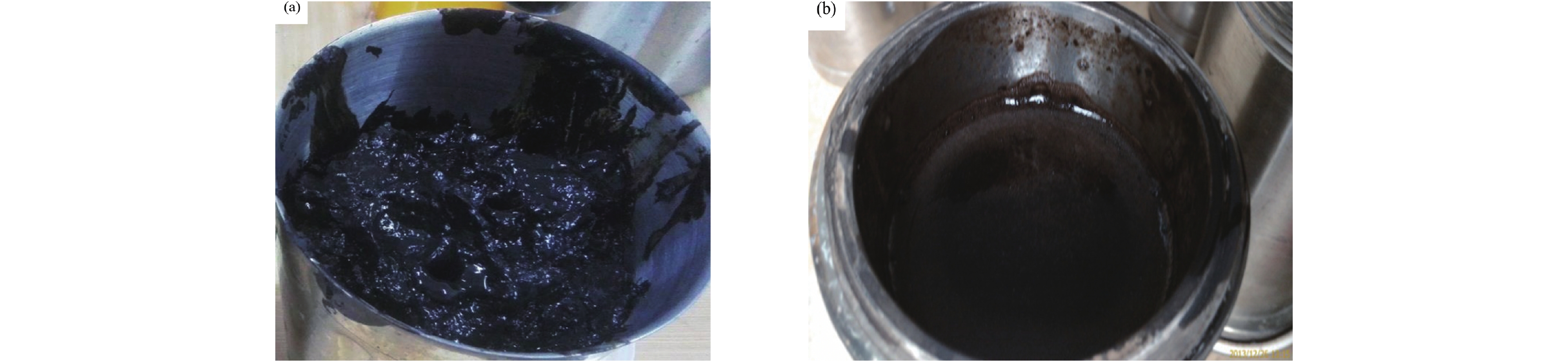

Figure 13.

Comparison of high temperature aged mud with different mud formulation. (a) conventional sulfonated system was congealed after aging at 220ºC. (b) Ultra-temperature water-based polymer system in the normal state after aging at 250ºC.

-

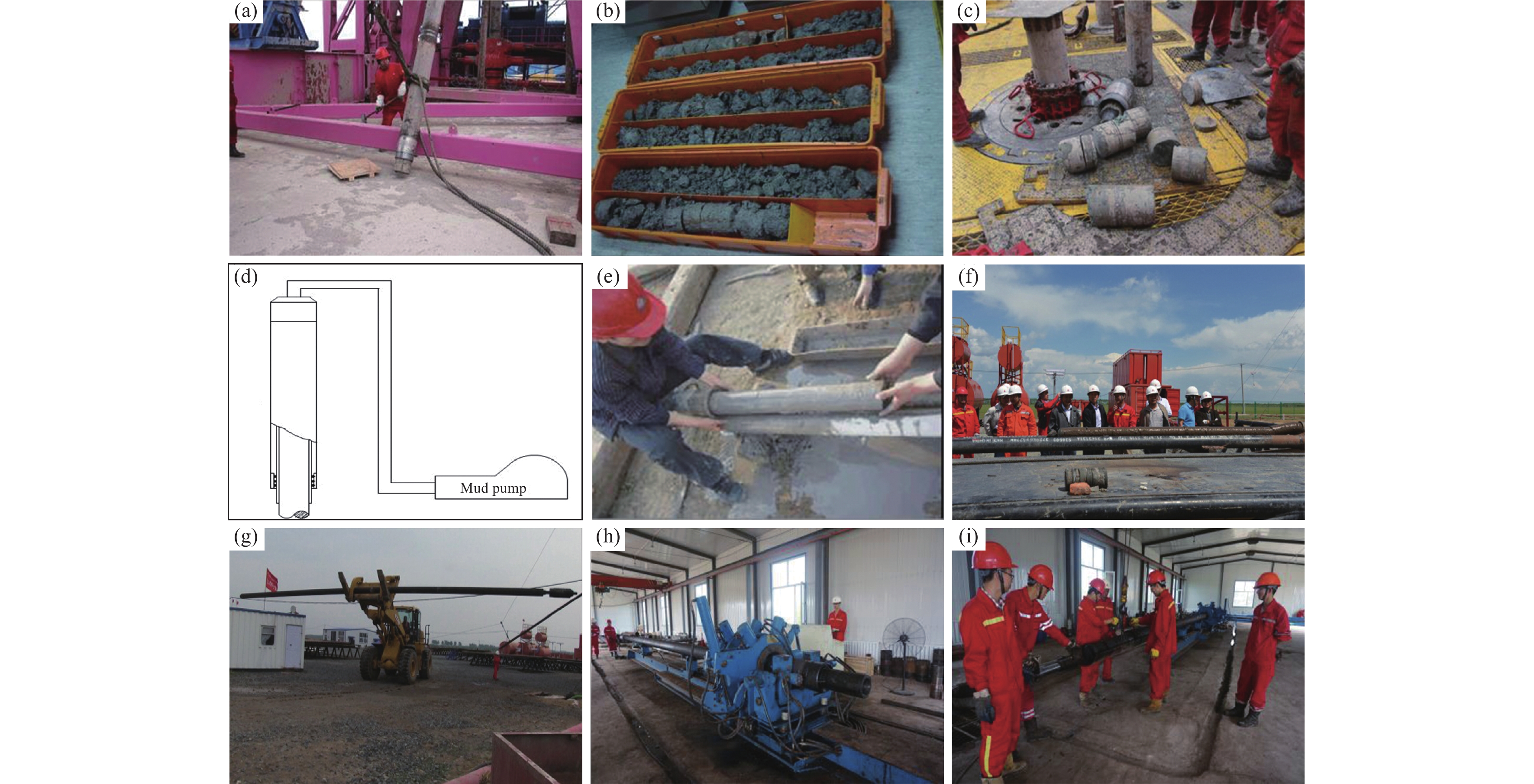

Figure 14.

Methods for pulling cores and its core samples. (a). The normal methods for pulling cores from the barrel. (b). The loose cores drilled from SK-I. (c). The hard cores drilled from SK-II. (d). Mechanism of pulling cores by water. (e) Using water to pull cores in SK-I. (f) Large scale of using water to pull cores in SK-II. Cores pushed out of barrel by machine. (g). The core barrel filled with cores is being carried to operating room; (h). The hydraulic disassembly and mounting bracket used for pushing hard core; (i). The φ214 mm diameter cores are being pushed out of core barrel by the hydraulic disassembly and mounting bracket.

DownLoad:

DownLoad: