| Citation: | Sun Jia-xing, Yue Gao-fan, Zhang Wei. 2023. Simulation of thermal breakthrough factors affecting carbonate geothermal-to-well systems. Journal of Groundwater Science and Engineering, 11(4): 379-390. doi: 10.26599/JGSE.2023.9280030 |

Simulation of thermal breakthrough factors affecting carbonate geothermal-to-well systems

-

Abstract

Fractures play a pivotal role in carbonate thermal storage systems, serving as primary hydraulic conductivity channels that significantly influence thermal breakthrough times and heat extraction efficiency in geothermal-to-well systems. Their impact is critical for well placement and system life prediction. This paper focuses on a geothermal-to-well system within the carbonate reservoir of the Wumishan formation in the Rongcheng geothermal field, Xiong'an new area. It employs a combination of field tests and numerical simulations to determine the permeability of the reservoir and the evolution of fractures between wells. It also examines the influence of fracture width and roughness coefficient on the seepage and temperature fields under various injection scenarios and predicts thermal breakthrough times for production wells. The results show: Higher permeability is observed near well D16 compared to well D22 within the studied geothermal-to-well systems. Wider fractures between wells result in faster temperature decline in production wells. Lower injection flow rates lead to slower temperature reduction in injection wells. The use of roughness coefficients minimizes temperature variations in production wells. This study not only offers guidance for the development and utilization of the geothermal well system, but also contributes to a deeper understanding of the groundwater seepage and heat transfer process influenced by fractures.

-

Keywords:

- Geothermal recharge /

- Influencing factor /

- Thermal breakthrough /

- Seepage field /

- Temperature field

-

-

References

Chen MX, Wang JY, Wang JA, et al. 1990. Characteristics of the thermal field and its formation mechanism in the North China Fracture Basin. Acta Geologica Sinica, 1990(01): 80−91. (in Chinese) DOI:10.19762/j.cnki.dizhixuebao.1990.01.008. Cheng WQ, Liu JL, Chen HB. 2011. Simulation study of the temperature field of geothermal extraction and irrigation on well recharge. World Geology, 30(03): 486−492. (in Chinese) DOI:10.3969/j.issn.1004-5589.2011.03.026. Dai MG, Wang XW, Liu JM, et al. 2019. Characteristics and influencing factors of geothermal resources in and around the start-up area of Xiong'an new area. Geoscience, 54(1): 16. (in Chinese) DOI:10.12017/dzkx.2019.011. Dong YX, Huang HX, Ren L, et al. 2021. Geology and development of geothermal field in Neogene Guantao Formation in northern Bohai Bay Basin: A case of the Caofeidian geothermal heating project in Tangshan, China. Petroleum Exploration and Development, 48(3): 775-786. He DF, Shan SQ, Zhang YY, et al. 2018. Three-dimensional geological structure of the Xiongan New Area: Constraints from reflection seismic data. China Science: Earth Science, 48(09): 16. (in Chinese) He MC, Li QM. 2005. Research on sustainable application of geothermal resource terracing development. Mining Research and Development, 2005(03): 37−40. (in Chinese) DOI:10.13827/j.cnki.kyyk.2005.03.013. Hong ZL, Zhang YL, Zhou Y. 2019. Fugitive characteristics and applications of mid-deep geothermal resources in the southern mountain front of the Guanzhong Basin. China Geology, 46(05): 12. (in Chinese) Li ZW. 2016. Study on dry heat rock fracture seepage−heat transfer test and reservoir simulation evaluation. Ph. D. thesis. Jilin University. (in Chinese) Lin WJ, Wang GL, Gan HN, et al. 2022. Heat source model for Enhanced Geothermal Systems (EGS) under different geological conditions in China. Gondwana Research, 2022, 122(3-4): 243-259. Liu YG, Liu GH, Zhao ZH, et al. 2019. Theoretical model of geothermal tail water reinjection based on an equivalent flow channel model: A case study in Xianxian, North China Plain. Energy Exploration & Exploitation, 37(2): 849-864. Long XT, Xie HP, Deng XP, et al. 2021. Geological and geochemical characteristics of the geothermal resources in Rucheng, China. Lithosphere, 2021(Special 5): 1357568. Lu K, Bao ZD, Ji HC, et al. 2019. Characteristics, main controlling factors and prediction of favorable area of karst thermal storage in the Jixian System Wushan Formation of Xiongan New Area. Journal of Paleogeography, 21(6): 16. (in Chinese) Luo S. 2018. Multiscale numerical analysis of seepage heat transfer problems in deep geothermal-to-well systems. Ph. D. thesis. Tsinghua University. (in Chinese) Ma F, Wang GL, Zhang W, et al. 2020. Spatial structure and resource potential of thermal storage in the Rongcheng geothermal field of Xiong'an New Area. Journal of Geology, 94(07): 1981−1990. (in Chinese) DOI:10.19762/j.cnki.dizhixuebao.2020217. Moya D, Aldas C, Kaparaju P. 2018. Geothermal energy: Power plant technology and direct heat applications. Renewable and Sustainable Energy Reviews, 94(OCT.): 889−901. DOI:10.1016/j.rser.2018.06.047. Pang ZH, Kong YL, Pang JM, et al. 2017. Research on geothermal resources and development and utilization in Xiong'an new area. Journal of the Chinese Academy of Sciences, 32(11): 1224−1230. (in Chinese) DOI:10.16418/j.issn.1000-3045.2017.11.007. Qu ZQ, Zhang W, Guo TK. 2017. Influence of different fracture morphology on heat mining performance of enhanced geothermal systems based on COMSOL. International Journal of Hydrogen Energy, 42(29): 18263-18278. Saeid S, Al-Khoury R, Hamidreza M. et al. 2015. A prototype design model for deep low-enthalpy hydrothermal systems. Renewable Energy, 77: 408−422. DOI:10.1016/j.renene.2014.12.018. Seyedrahimi-Niaraq M, Ardejani FD, Noorollahi Y, et al. 2019. A three-dimensional numerical model to simulate Iranian NW Sabalan geothermal system. Geothermics, 77: 42-61. Shan DD, Yan T, Li W, et al. 2019. Numerical simulation of coupled heat flow between random fracture network reservoir and wellbore. Natural Gas Industry, 39(07): 143−150. (in Chinese) Shan DD, Yan T, Li W, et al. 2020. Numerical simulation analysis of heat flow coupling in single fissure thermal storage. Contemporary Chemical Industry, 49(04): 716−719+723. (in Chinese) DOI:10.13840/j.cnki.cn21-1457/tq.2020.04.051. Sun YK, Liu F, Wang H, et al. 2022. Numerical simulation of operation performance on production and injection of a double well geothermal system in Kailu Basin, Inner Mongolia. Journal of Groundwater Science and Engineering, 10(02): 196−208. DOI:10.19637/j.cnki.2305-7068.2022.02.008. Sun ZX, Jiang CY, Zhang K, et al. 2020. Numerical simulation of THM coupling in CO2 enhanced geothermal system based on discrete fracture model. Journal of China University of Petroleum (Natural Science Edition), 44(06): 9. (in Chinese) DOI:10.3969/j.issn.1673-5005.2020.06.010. Tang BN. 2020. Study on the convergence mechanism of geothermal resources in karst thermal storage in Xiongan New Area. M. S. thesis. China University of Petroleum (Beijing). (in Chinese) Wang GL, Liu GH, Zhao ZH, et al. 2019. A robust numerical method for modeling multiple wells in city-scale geothermal field based on simplified one-dimensional well model. Renewable Energy, 139: 873−894. DOI:10.1016/j.renene.2019.02.131. Wei SC, Liu F, Zhang W, et al. 2022. Research on the characteristics and influencing factors of terrestrial heat flow in Guizhou Province. Journal of Groundwater Science and Engineering, 10(02): 166−183. DOI:10.19637/j.cnki.2305-7068.2022.02.006. Xiao P, Dou B, Tian H, et al. 2021. Numerical simulation study on seepage heat transfer in single fracture rock of geothermal reservoir. Drilling Engineering, 48(2): 16-28. (in Chinese) Zhang C, Jiang GZ, Jia XF, et al. Parametric study of the production performance of an enhanced geothermal system: A case study at the Qiabuqia geothermal area, northeast Xizang plateau. Renewable Energy, 2018, 132(MAR.): 959-978. Zhang SG, Xu YH. 2011. Three-dimensional finite element model for flow-thermal coupling of fractured rock masses. Journal of Liaoning University of Engineering and Technology (Natural Science Edition), 30(4): 3. (in Chinese) Zhu JL, Hu KY, Lu XL, et al. 2015. A review of geothermal energy resources, development, and applications in China: Current status and prospects. Energy, 93: 466−483. DOI:10.1016/j.energy.2015.08.098. Zhu X, Wang GL, Ma F, et al. 2022. Evaluation of geothermal resource potential in Xiongan New Area. Earth Science, 48(3): 1093−1106. (in Chinese) DOI:10.3799/dqkx.2022.200. -

Access History

-

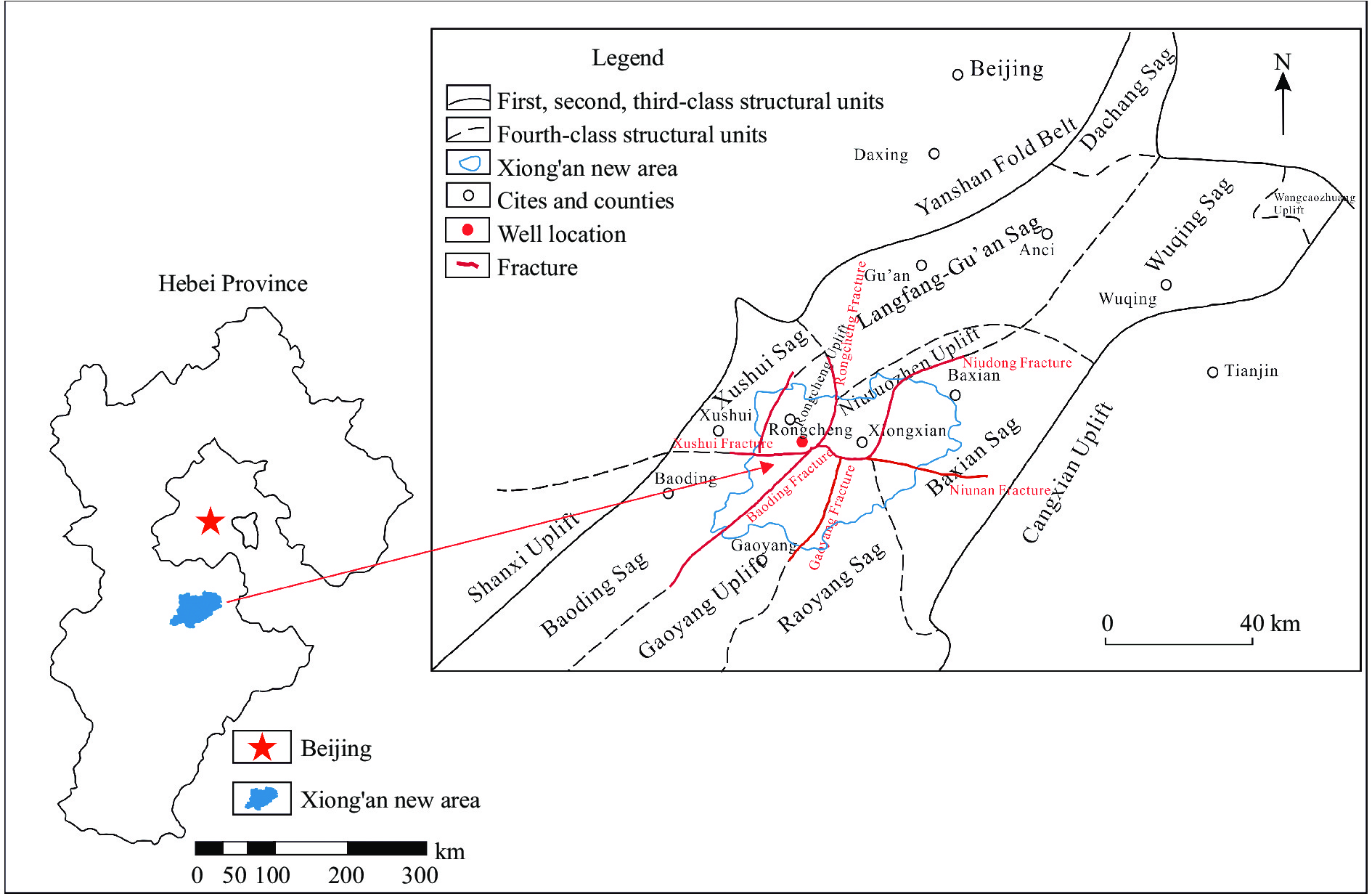

Figure 1.

Tectonic background map of Xiong'an new area

-

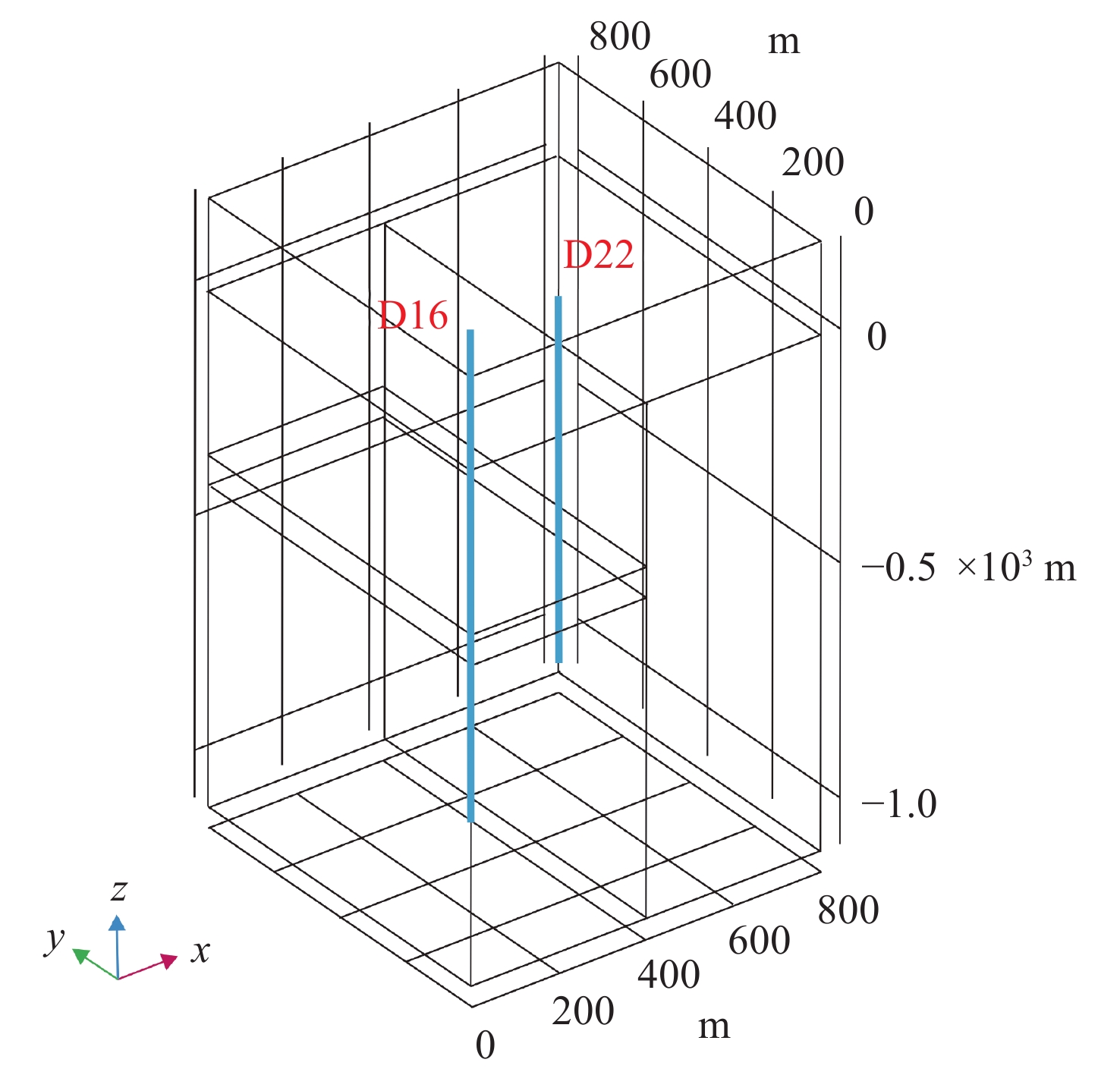

Figure 2.

Schematic diagram of the model

-

Figure 3.

Mesh sectioning case diagram

-

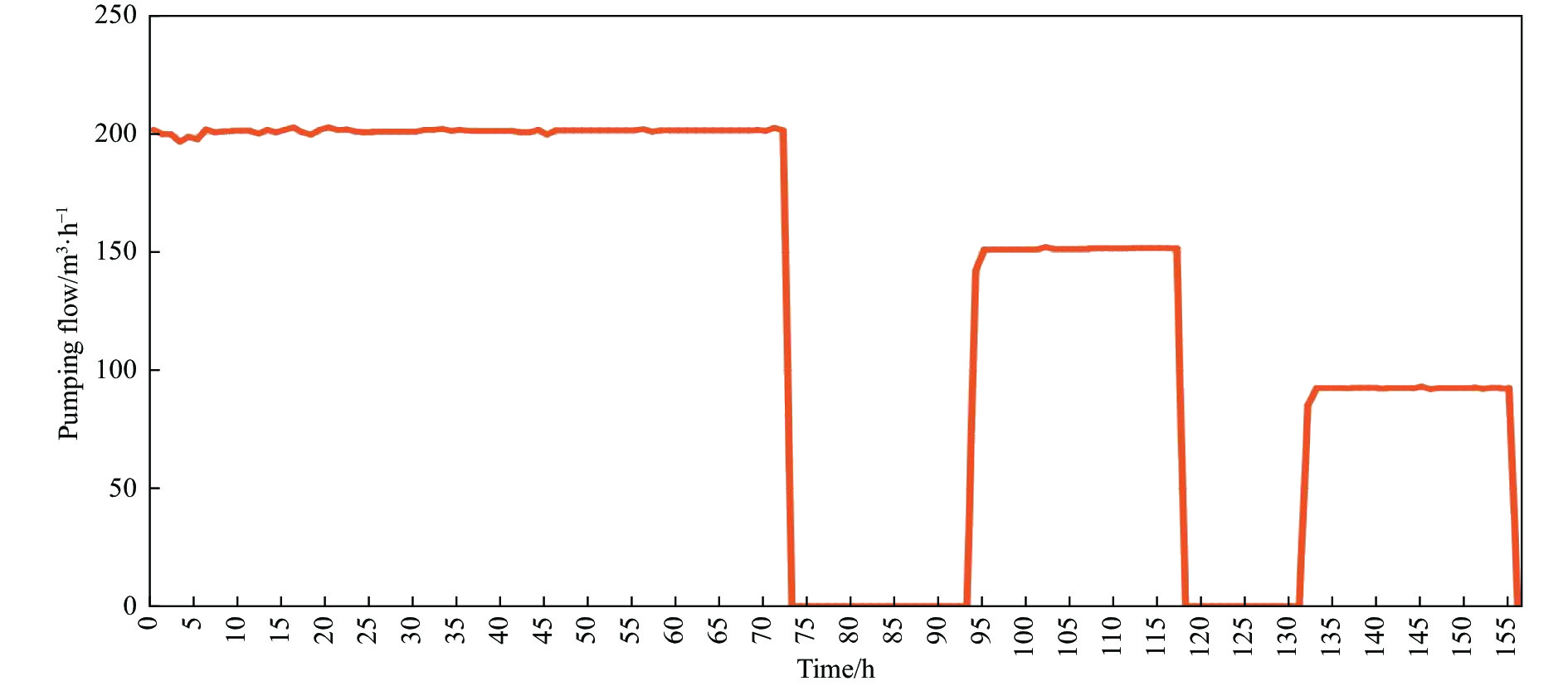

Figure 4.

Pumping flow conditions

-

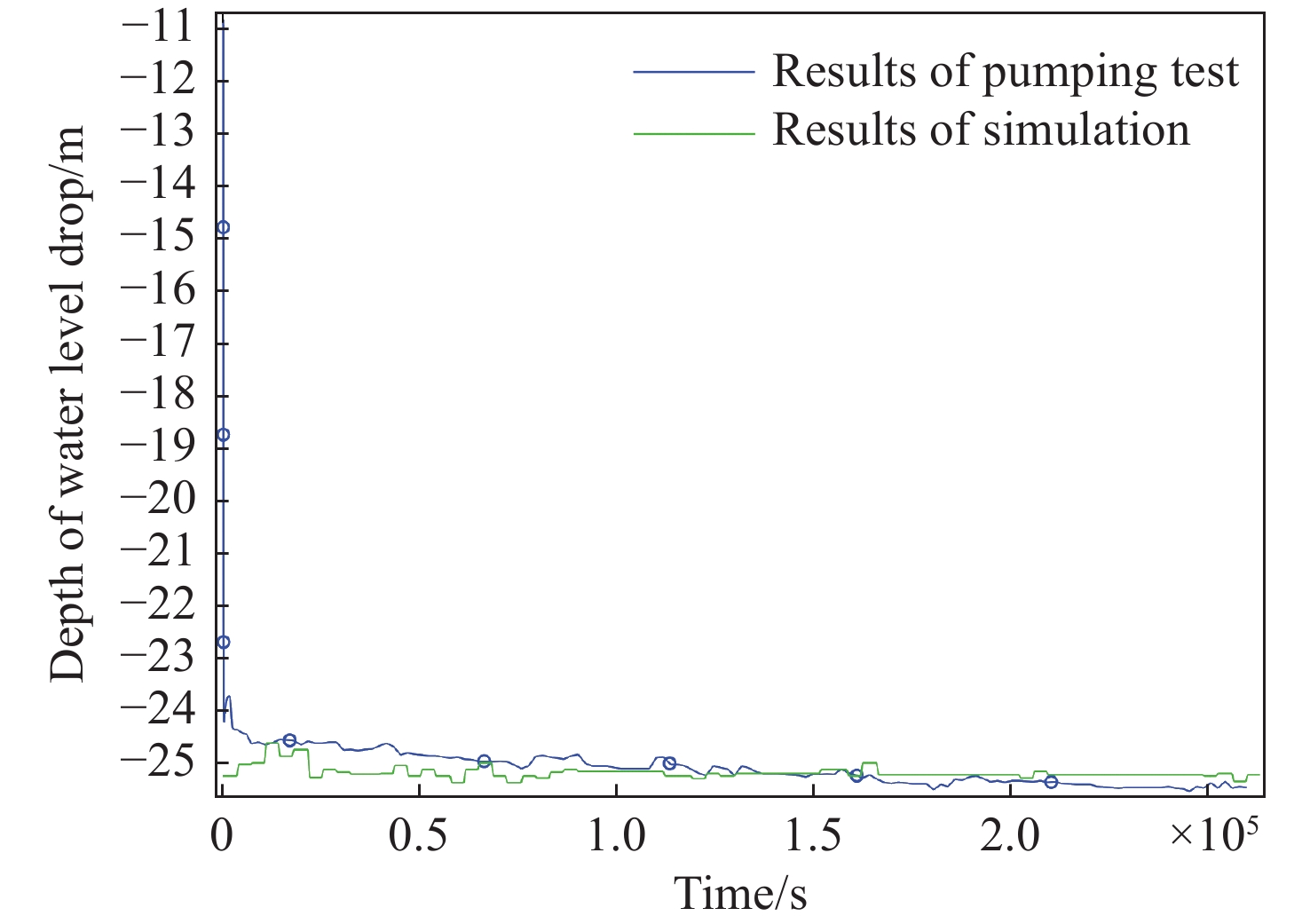

Figure 5.

Well D16 fitting results

-

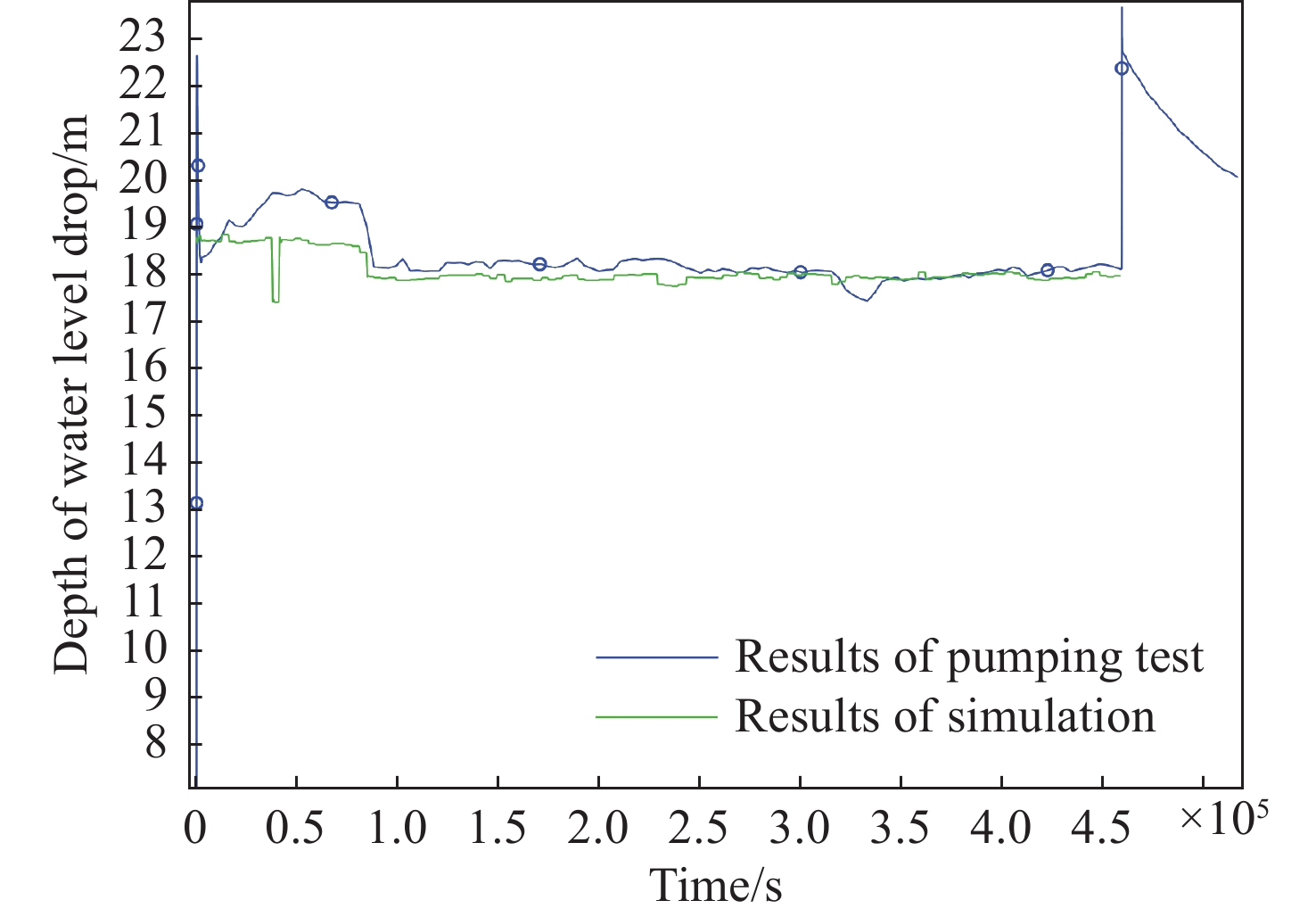

Figure 6.

Well D22 fitting results

-

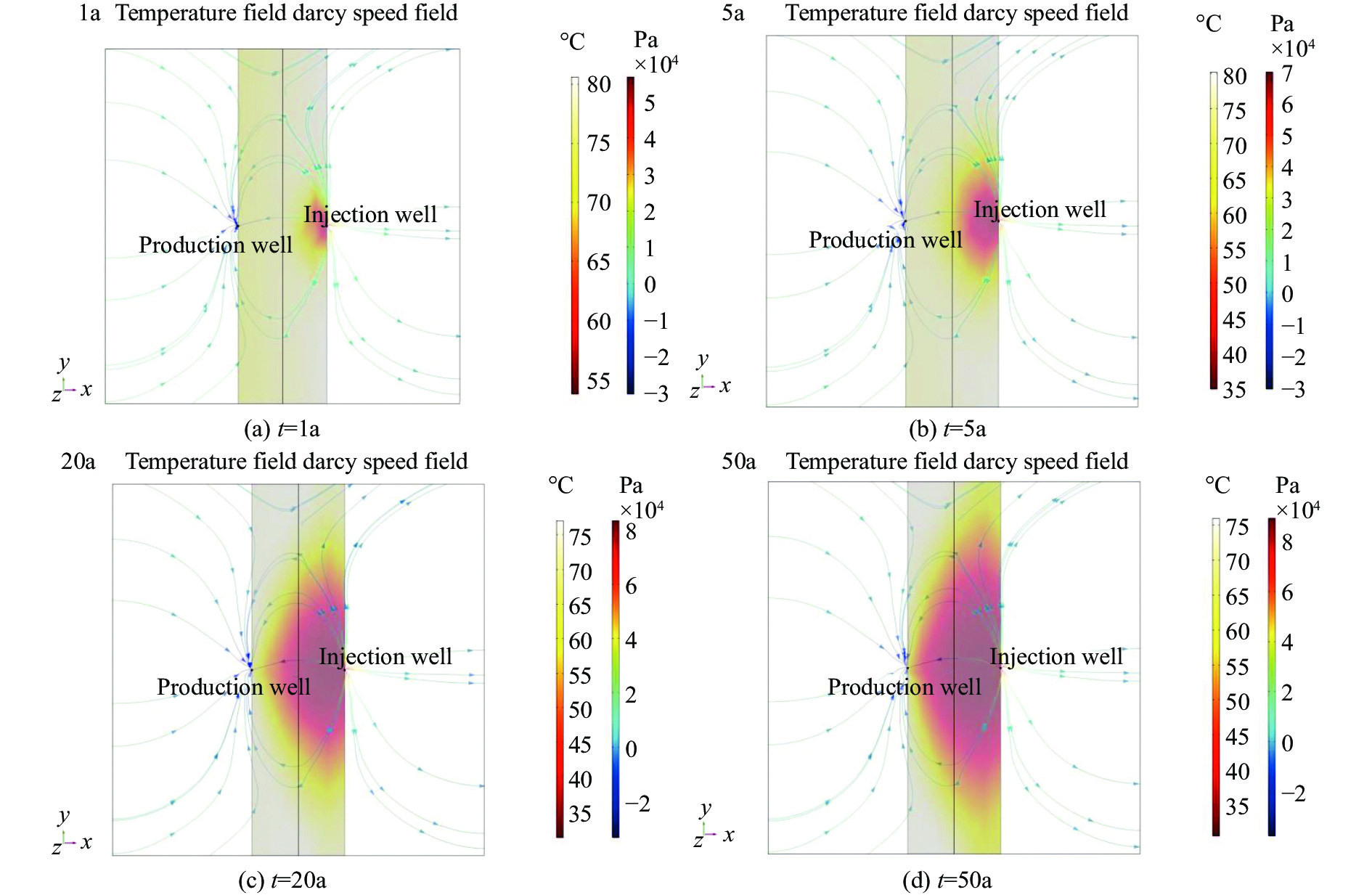

Figure 7.

Linear fit of actual water level drop to simulated water level drop (42 data sets)

-

Figure 8.

Variation of seepage and temperature fields after 1 year (a), 5 years (b), 20 years (c), 50 years (d) of production

-

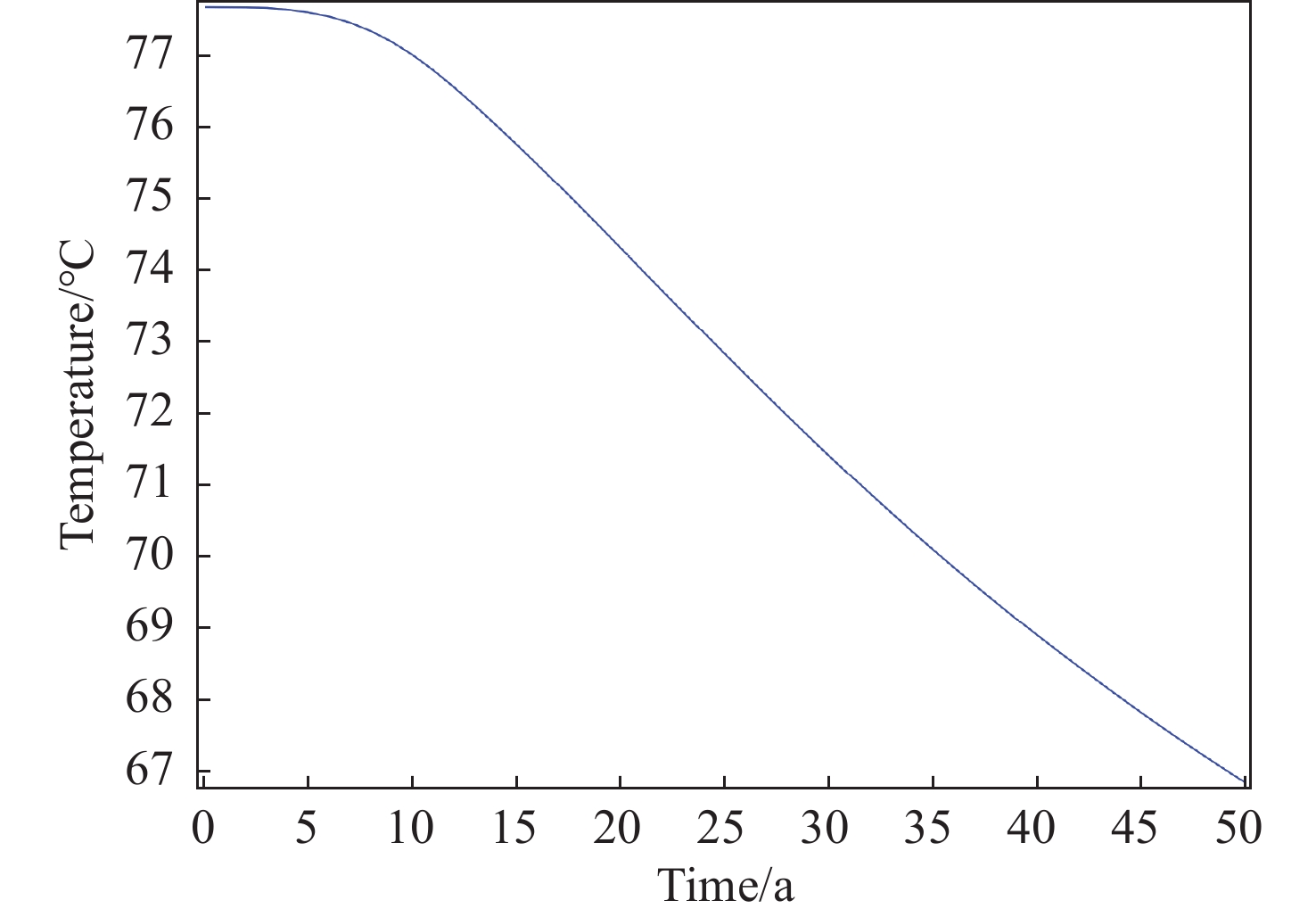

Figure 9.

Plot of temperature changes over 50 years in production wells

-

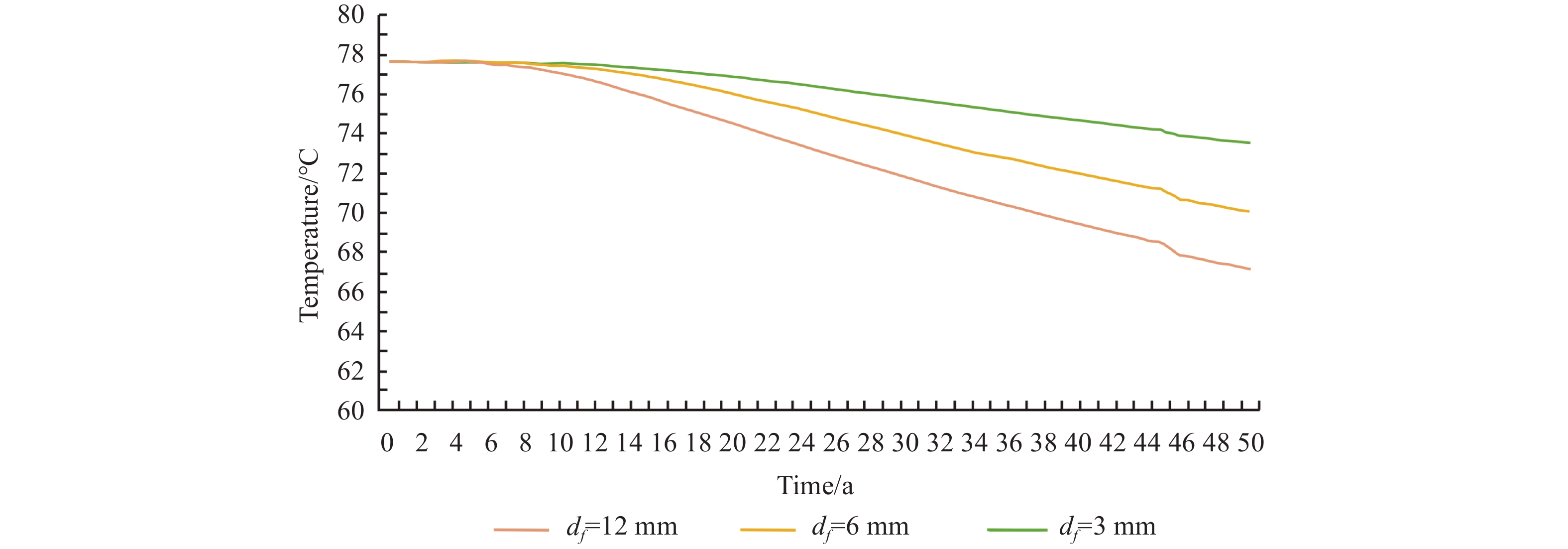

Figure 10.

Effect of different fracture widths on production well temperature

-

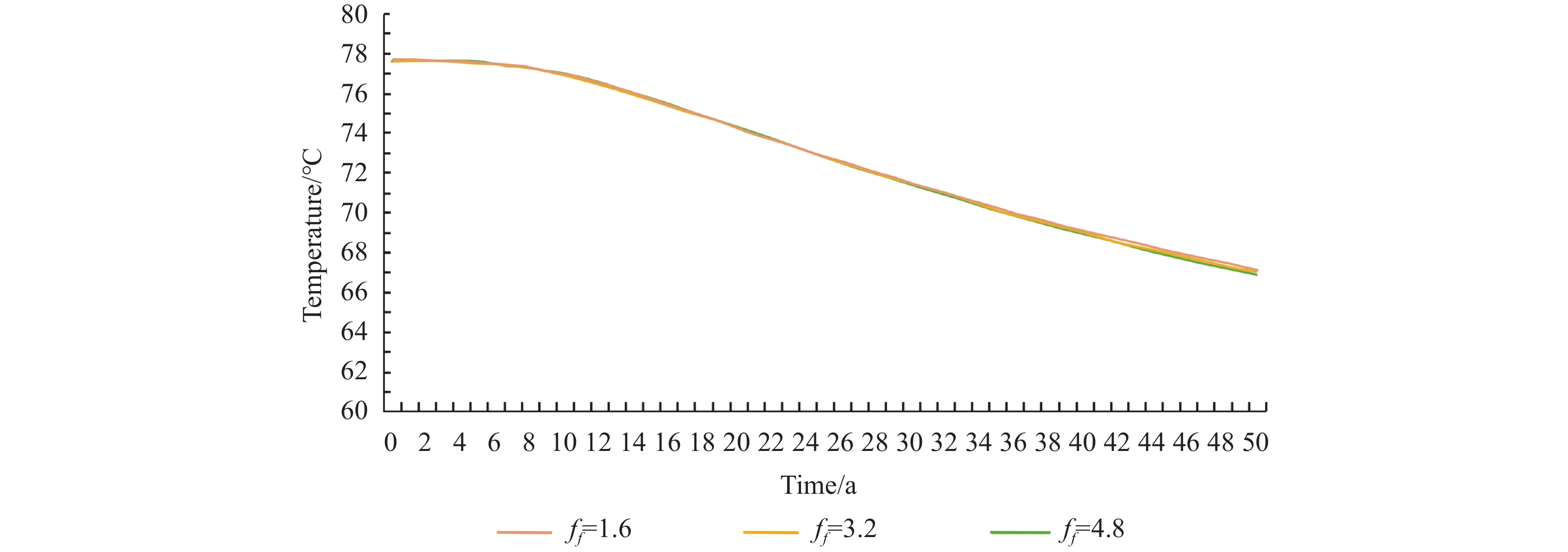

Figure 11.

Effect of different roughness coefficients on production well temperature

-

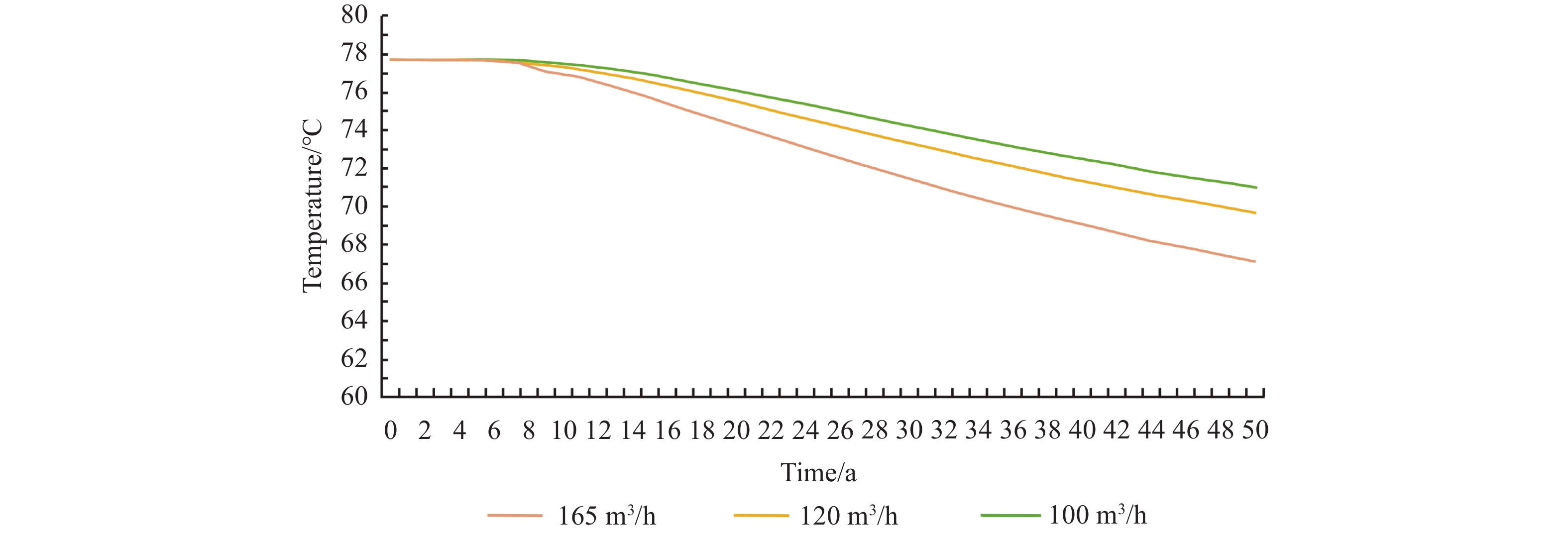

Figure 12.

Effect of different injection flow rates on temperature of production well

DownLoad:

DownLoad: