Sen YANG, Qingfei XIAO, Huaibin KANG, Shuai MA, Qian ZHANG, Xudong WANG. Research on Optimizing Particle Size Composition of Grinding Products of Dongguashan Copper Mine to Improve Flotation Index[J]. Conservation and Utilization of Mineral Resources, 2020, 40(4): 70-74. doi: 10.13779/j.cnki.issn1001-0076.2020.07.003

| Citation: |

Sen YANG, Qingfei XIAO, Huaibin KANG, Shuai MA, Qian ZHANG, Xudong WANG. Research on Optimizing Particle Size Composition of Grinding Products of Dongguashan Copper Mine to Improve Flotation Index[J]. Conservation and Utilization of Mineral Resources, 2020, 40(4): 70-74. doi: 10.13779/j.cnki.issn1001-0076.2020.07.003

|

Research on Optimizing Particle Size Composition of Grinding Products of Dongguashan Copper Mine to Improve Flotation Index

-

Sen YANG1,3,

-

Qingfei XIAO1,2,3, , ,

-

Huaibin KANG4,

-

Shuai MA1,3,

-

Qian ZHANG1,3,

-

Xudong WANG1,3

-

1.

Provincial and Ministry Jointly Establish National Key Experiments for Clean Utilization of Complex Nonferrous Metal Resources, Kunming 650093, China

-

2.

State Key Laboratory of Mineral Processing Science and Technology, Beijing 100070, China

-

3.

College of Land and Resources Engineering, Kunming University of Science and Technology, Kunming 650093, China

-

4.

Tongling Nonferrous Group Holding Co., Ltd. Dongguashan Copper Mine, Tongling 244031, China

More Information

-

Corresponding author:

Qingfei XIAO, 13515877@qq.com

-

Abstract

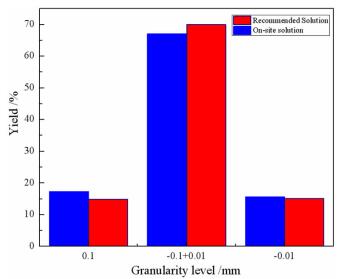

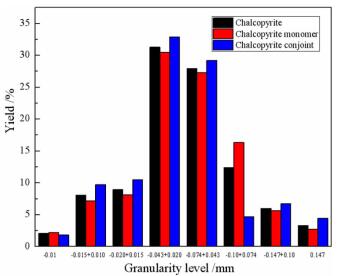

In order to solve the problem of coarse and unreasonable particle size composition distribution in Dongguashan, the particle size composition of floating particles was optimized by adjusting the proportion of grinding medium based on the particle size distribution of grinding products and the dynamics properties of ores. The results showed that the size scheme of one stage of grinding media in Dongguashan is m (φ60):m (φ40):m (φ30):m (φ25) = 40:10:30:20. The yield of -0.1+0.01mm particles in grinding mineral products could be increased by 2.28% used the recommended scheme. Compared with the recommended scheme and the field scheme experienced flotation closed circuit test with one rough and two fine sweeps, the recovery rate of copper concentrate used recommended scheme was 90.11%, which was 1.34% higher than that of the field scheme. And the concentrate grade used recommended scheme was 0.94% higher than that of the field scheme. According to the screening and detection analysis of the flotation tailings, the recovery of copper in -0.1+0.01mm particles of grinding minerals in the recommended scheme was better than that in the field scheme. The recommended medium ratio scheme was used to optimize the particle size composition of grinding minerals, which effectively improved the flotation index of copper in Dongguashan.

-

-

References

| [1] |

周平.新常态下中国铜资源供需前景分析与预测[D].北京: 中国地质大学(北京), 2015.

Google Scholar

|

| [2] |

苏敏, 窦培谦, 张瑞洋, 等.谦比希铜矿中铜矿物的解离特性及其可浮性研究[J].金属矿山, 2019(4):105-110.

Google Scholar

|

| [3] |

王素, 齐向红, 田江涛, 等.河北省某铜尾矿综合回收试验研究[J].矿产综合利用, 2019(3):113-117.

Google Scholar

|

| [4] |

HOSSEINI, FORSSBERG. Studies on selective flotation of smithsonite from silicate minerals using mercaptans and one stage desliming[J]. Mineral Processing and Extractive Metallurgy, 2011, 120(2):79-84.

Google Scholar

|

| [5] |

蒋婷婷, 熊巍.江西地区铜矿工艺矿物学特征及选矿影响因素研究[J].中国金属通报, 2019(10):70-72.

Google Scholar

|

| [6] |

薛季玮, 姚金, 唐远, 等.粒度对蓝辉铜矿与黄铁矿浮选分离特性的影响[J].金属矿山, 2018(8):73-78.

Google Scholar

|

| [7] |

汪太平, 肖庆飞, 李博.冬瓜山铜矿一段磨矿产品粒度组成优化研究[J].矿产保护与利用, 2014(4):22-26 doi: 10.13779/j.issn.1001-0076.2014.04.006

CrossRef Google Scholar

|

| [8] |

康怀斌.大山选厂浮选回收率与磨矿产品粒度均匀性的多元线性回归模型及应用研究[D].昆明: 昆明理工大学, 2015.

Google Scholar

|

| [9] |

杨金林, 莫凡, 周文涛, 等.选择性磨矿研究概述[J].矿产综合利用, 2017(5):1-6

Google Scholar

|

| [10] |

王翠花, 支永勋, 李学忠.选择性磨矿在萤石矿选矿工艺中的应用[J].化工矿物与加工, 2013, 42(6):37-39.

Google Scholar

|

| [11] |

邓禾淼, 康怀斌, 肖庆飞.改善冬瓜山铜矿磨矿效果提高铜回收率的研究[J].有色金属(选矿部分), 2017(1):65-68.

Google Scholar

|

| [12] |

王改荣, 杨洪英, 佟琳琳, 等.赞比亚卢安夏氧化铜矿工艺矿物学研究[J].东北大学学报(自然科学版), 2019, 40(3):350-355.

Google Scholar

|

| [13] |

肖庆飞, 康怀斌, 张红华, 等.优化球荷特性提高磨矿产品粒度均匀性的研究[J].矿产保护与利用, 2015(5):25-28. doi: 10.13779/j.cnki.issn1001-0076.2015.05.005

CrossRef Google Scholar

|

| [14] |

段希祥, 肖庆飞.碎矿与磨矿[M].北京:冶金工业出版社, 2012:1-5.

Google Scholar

|

-

-

Access History

DownLoad:

DownLoad: